|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TO 14P3-5-61

Section IV

Paragraph 4-10A

to touch and place coated side of patch to coated side of

garment.

e. Center patch over damaged area (Figures 4-6,

channels. Dust repaired area with talc.

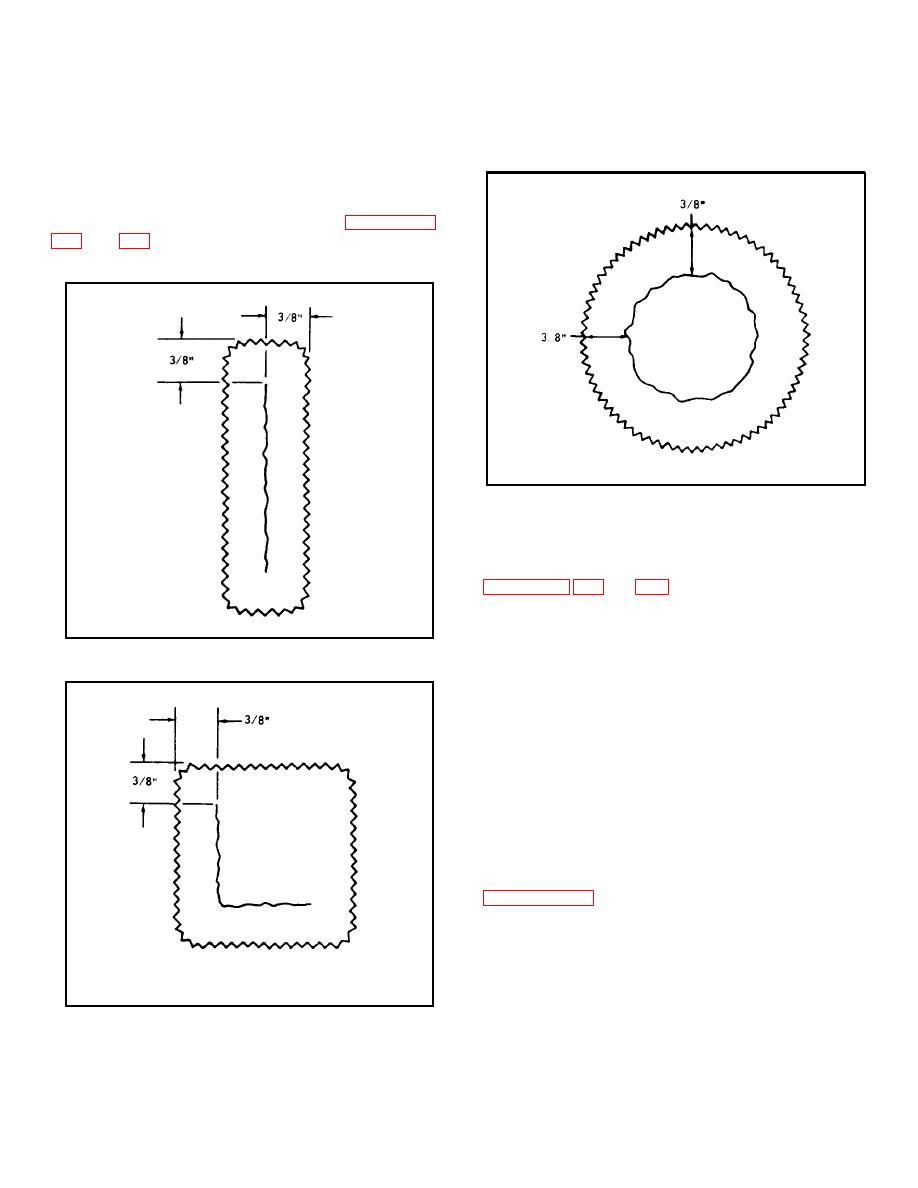

Figure 4-8. Round Patch

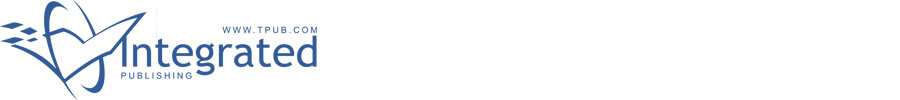

f. Patches will be square, circular. or rectangular

in shape with rounded corners and cut large enough to

extend 3/8-inch beyond the edge of defect as shown in

slightly larger than the patch to prevent loose edges.

g. Thin areas of coating and minute holes or

Figure 4-6. Rectangular Patch

punctures in coverall. especially in area of the slide

fastener, may be repaired as follows:

(1) Wipe abraded area with acetone to insure

area free of foreign matter and dusting powder.

(2) Brush on two very light coats of MIL-A-55

allowing coat to dry before applying second coat. Allow

second coat to dry thoroughly and dust brushed area

lightly with talc.

4-10A. Hood and gloves requiring repair due to snags,

tears, or punctures will be repaired as outlined in

gloves will be limited to not more than three patches per

glove and each patch will not exceed 3 square inches in

size.

NOTE

All patches will be cemented to the outside of hood

and gloves.

Figure 4-7. Rectangular Patch(Puncture)

Change 23 4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |