|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TB 9-2300-247-40

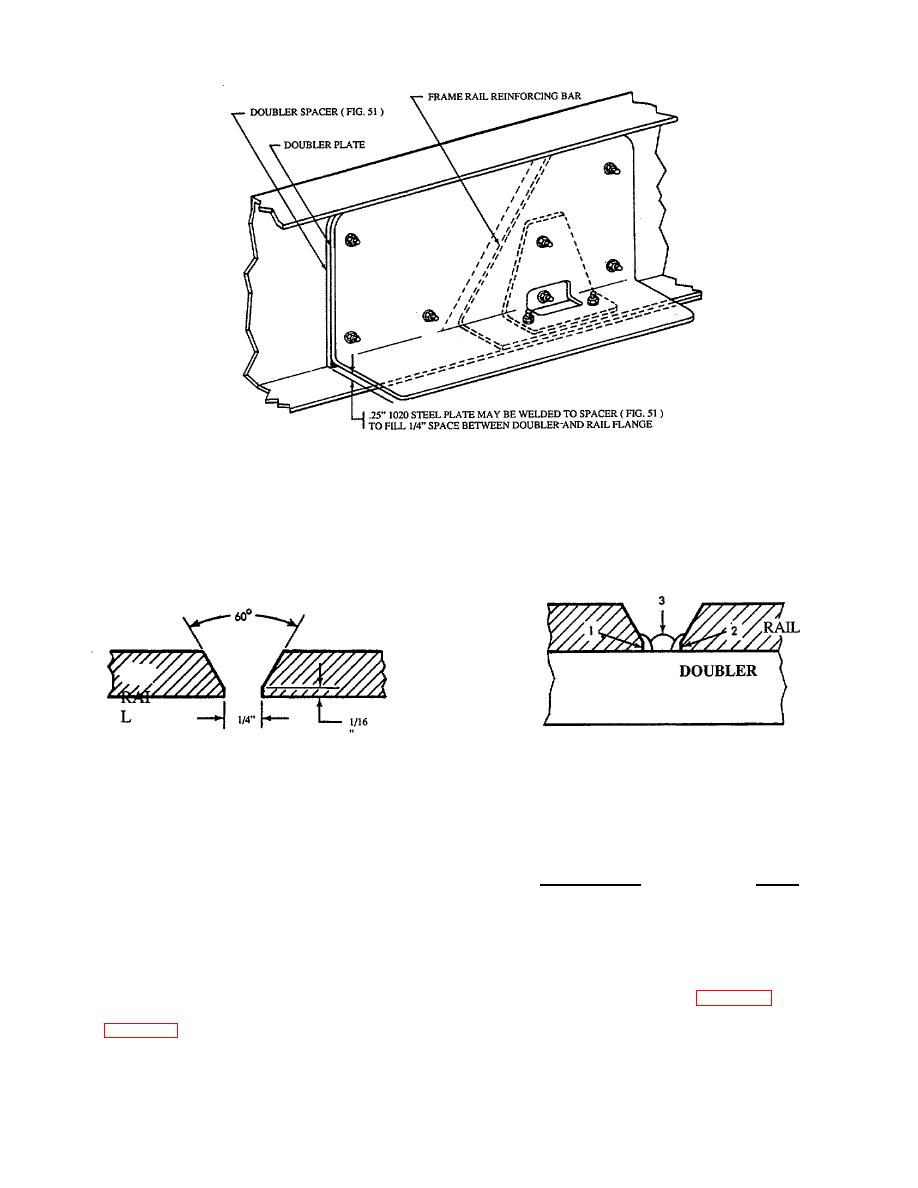

Figure 52. Inner View - Jounce Bracket

nature of the defect and the method of repair.

63.

Welding Frame Rails.

c.

Welding Electrodes. Perform all welding using

a. Cleaning. Thoroughly clean frame rail to be

electrode type MIL-312, Specification 12018-M

welded of all grease, asphalt, dirt, or other

of AWS-A5 in sizes 3/32-inch, 1/8-inch, and

debris.

5/32-inch diameters.

b. Inspection. Inspect frame rail to determine

Figure 54. Groove Welding Passes

Figure 53. Typical Root Groove

Perform initial welding passes as indicated in

WARNING

Figure 55.

Use only effective chip guarding

g. Recommended welding current for flat welding is

equipment, protective equipment and

as follows:

protective clothing (goggles, shields,

gloves aprons, etc) when doing any

Electrode size

DCRP

drilling, grinding, or welding. Failure

3/23

50-75

to follow this warning could result in

1/8

75-95

injury to personnel.

5/32

90-135

d. Preheating. Preheat frame rails between 4500 F

h. Beading. Deposit the first layer of weld metal

and 5500 F before welding.

with three passes of a 3/32-inch diameter

electrode. as shown in Figure 49, using stringer

e. Grooving.

Groove all cracks as indicated in

beads. Where vertical welding is required, such

passes may be up or down. A weave pass may

be used in vertical-up pass in the rail face and

f.

Groove Welding. Use sizes 3/32-inch and 1/8-

inch electrodes for groove welding.

45

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |