|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

MAINTENANCE:

AXLES:

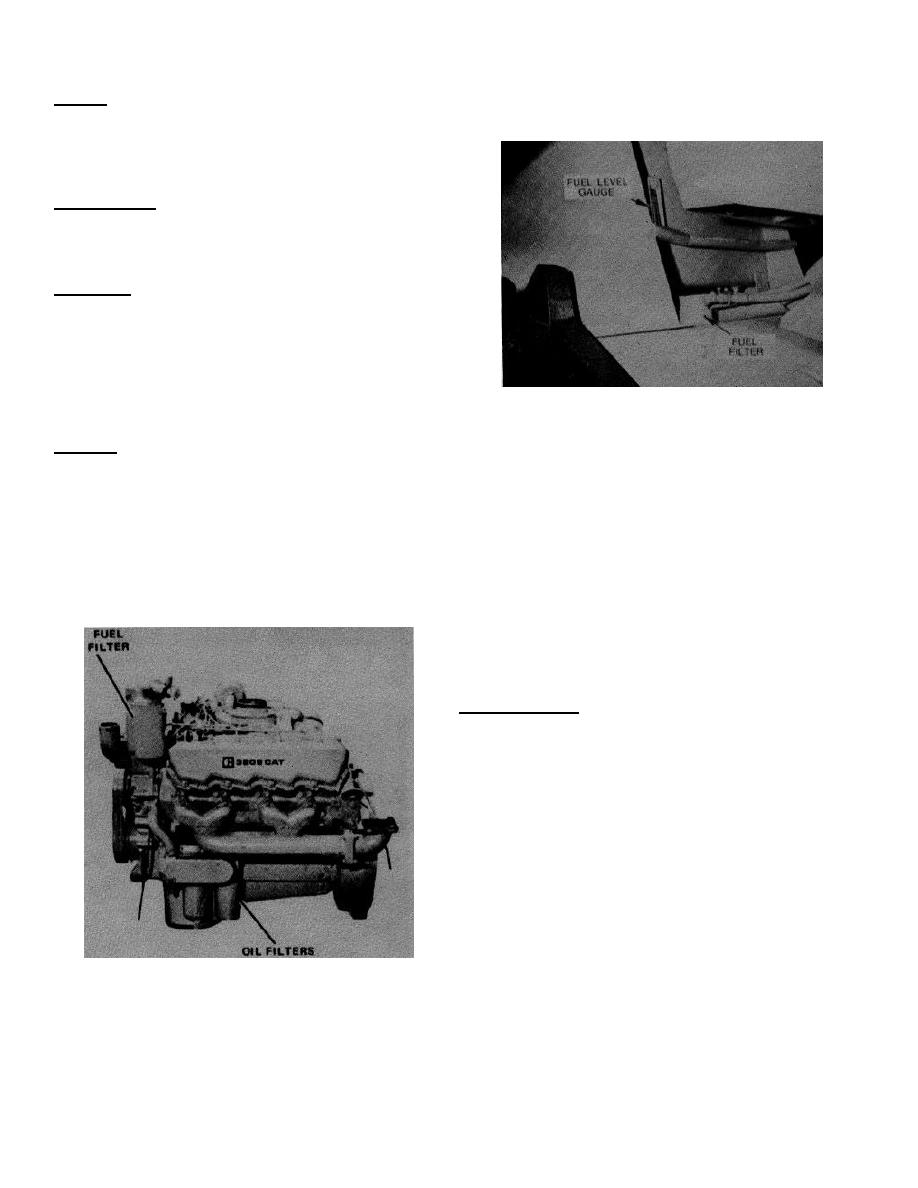

CHANGE FUEL FILTER every 200 hours, located on

underside of fuel tank and on engine.

CHECK WHEEL MOUNTING NUTS regularly and torque

to 450 ft-lbs (62 m-kg). Loose wheel nuts will strain axle

assemblies and affect steering and load distribution.

CHECK FOR CYLINDER LEAKAGE OR DAMAGE.

Excessive leakage may require seal replacement.

GENERAL:

INSPECT ALL MOUNTED PARTS FOR looseness or

noticeable damage.

200 Hours:

CHANGE AIR FILTER ELEMENT.

Refer to vendor

ENGINE:

literature for recommended service procedure.

CHANGE ENGINE OIL AND FILTER after machine

CHECK THROTTLE LINKAGE to see if in good operating

operation as hot oil will drain away sediment. Refer to

condition. Make sure that linkage travel is free and

vendor engine manual for detailed instructions.

unhindered.

RECORD OIL PRESSURE after oil change with oil at

ADJUST VALVES after the first 200 hours of operation.

operating temperature and engine at idle. Comparative

Thereafter, valve adjustment is required only every 800

readings will give an indication of progressive wear of

hours. Refer to vendor manual for detailed instructions.

engine components.

TRANSMISSION:

CHANGE OIL FILTER every 200 hours with transmission oil

at operating temperature of 180 to 200 (82 to 93 ).

F

C

Remove sump screen, cleaning thoroughly and replace

using new gaskets. Access to the filter can be made by

removing rear floor plate and seat mounting base, complete

with seat. Using a chain or belt filter wrench, remove

canister. Remove old element and check for foreign

material de- posits. Install new element and O ring. Install

filter canister and torque to20 to 25 ft-lbs (2,8 to 3,5 m-kg).

Idle engine and check oil level, adding fluid as necessary

(refer to LUBRI- CANTS SPECIFICATION CHART).

K300

Rev. 760501

400-4.6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |