|

|||

|

|

|||

|

Page Title:

HYDRAULIC CYLINDERS |

|

||

| ||||||||||

|

|

HYDRAULIC CYLINDERS

MAINTENANCE:

REMOVE

DEBRIS

FROM

AROUND

DOZER

CYLINDER daily to avoid damage to cylinder rod.

CHECK CYLINDERS FOR LEAKAGE every 100 hours.

Excessive leakage may require seal replacement.

STEERING CYLINDER REMOVAL:

1. Park machine on level ground, set parking brake

and lower blade.

2. Secure steering wheel so that valve cannot be

opened, as this would result in loss of hydraulic fluid.

3. Remove front and rear floor plates. Remove

engine side guards.

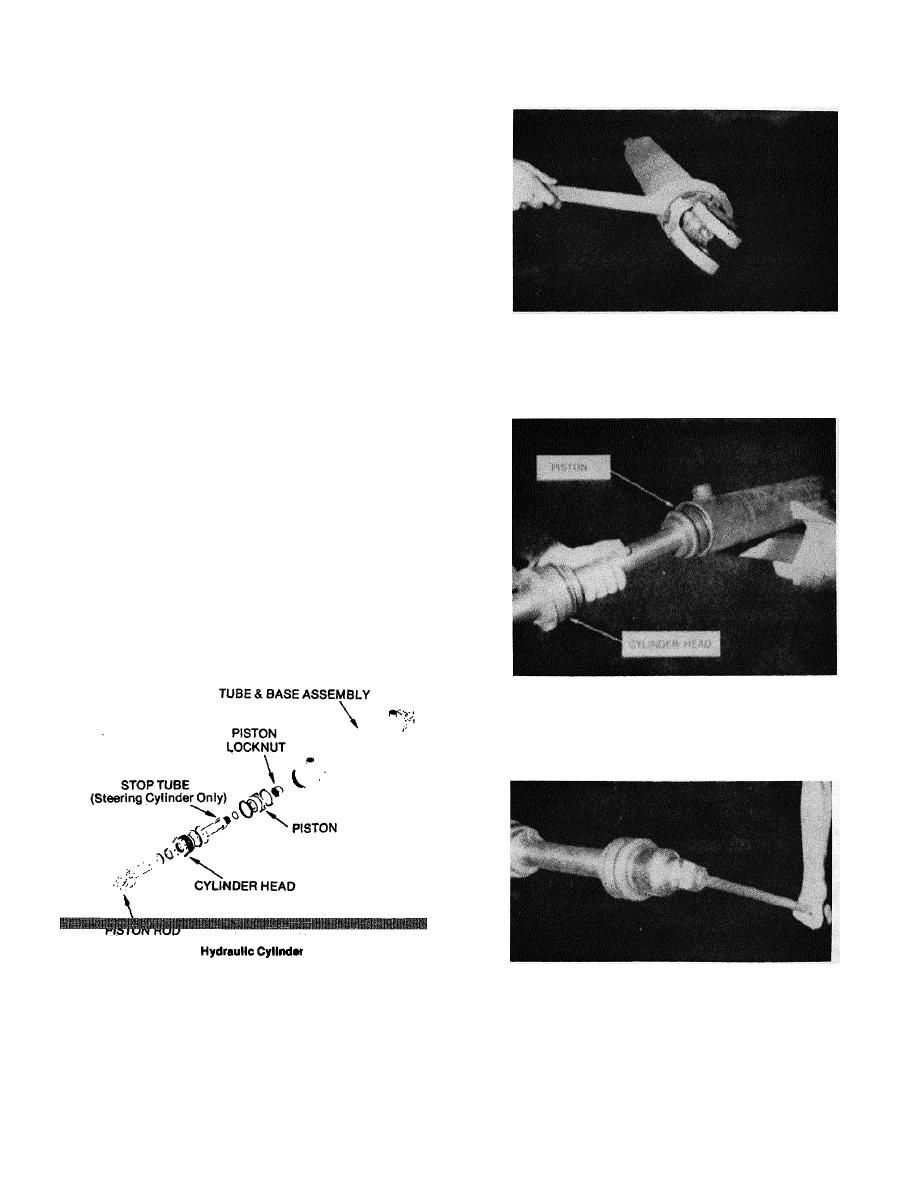

Removing Cylinder Head

4. Disconnect all steering hoses at the cylinder and

cap.

3.

Remove piston and piston shaft from cylinder

5. After removing cotter pin, remove steering cylinder

tube.

clevis pins.

6. Remove cylinders from machine.

7. Reverse procedure for installation.

DOZER CYLINDER REMOVAL:

1. Park machine on level ground, set parking brake

and lower blade.

2. After removing cotter pin, remove lower cylinder

clevis pin.

3. Retract dozer cylinder shaft.

4. Secure dozer control lever in HOLD position so

that valve cannot be opened, as this would result in loss

of hydraulic fluid.

5. Disconnect and cap dozer cylinder hoses.

6. Sling cylinder and remove upper cylinder cotter

and clevis pin.

7. Reverse procedure for installation.

4. Inspect cylinder tube, shaft and head for scoring

or pitting.

5. Remove nut on end of piston shaft and remove

piston from piston shaft.

Removing Piston Shaft End Nut

SEAL REPLACEMENT:

1. After removing cylinder from machine, drain oil

and secure on bench.

2. Using proper wrench, loosen head of cylinder.

K300

60-5.1

Rev. 760501

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |