|

|||

|

|

|||

|

Page Title:

Reassembly of Differential and Carrier (CONT) |

|

||

| ||||||||||

|

|

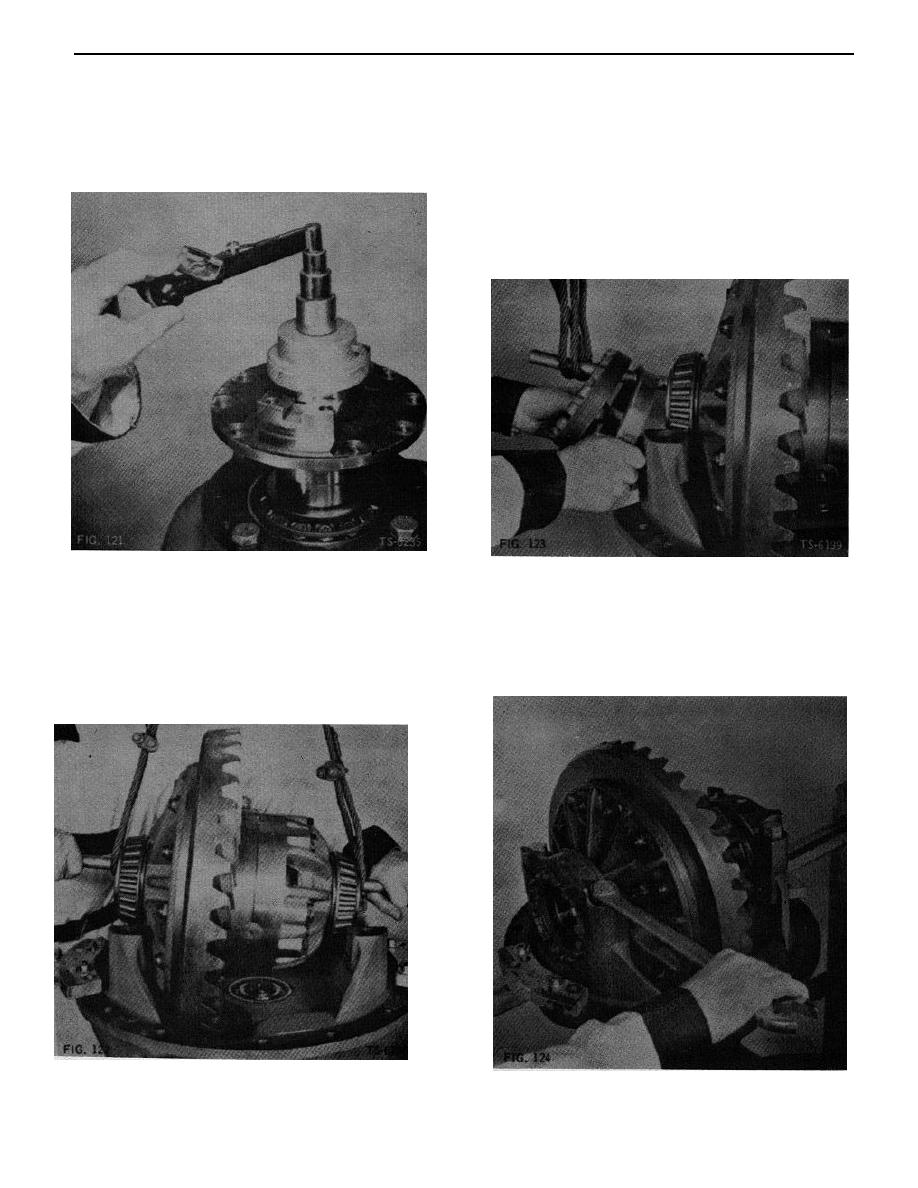

3. Use "inch-pound" torque wrench to check bearing

5. Position differential bearing cup and differential

preload (Fig. 121). If bearing preload is not between

adjusting nut on lifting bar on one side of differential

13 and 23 in. lbs., disassemble parts and add shims

and lift bar slightly with hoist. Position bearing cup

to decrease preload or remove shims to increase

and adjusting nut on carrier (Fig. 123). Repeat

preload.

procedure to install opposite bearing cup and

adjusting nut. Take care to prevent cross-threading of

nuts.

NOTE: If differential bearing Cones are replaced,

new bearing cups must be used.

FIG. 121

FIG. 123

4. Position differential carrier and pinion assembly in

6. Position bearing caps on bearings and nuts, making

differential stand so that pinion shaft is down. Insert

sure match-marks made during disassembly are

bar through differential to facilitate' hoisting. Position

properly aligned. Install bearing cap bolts (Fig. 124)

differential into carrier, tilting it so that ring gear will

and tighten until snug, but do not torque. Rotate

clear inner bearing boss in carrier (Fig. 122).

adjusting nuts from time to time to assure that they

are not crossthreaded.

NOTE: If differential bearing cones are replaced it is

also necessary to replace differential bearing cups.

FIG. 122

FIG. 124

39

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |