|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

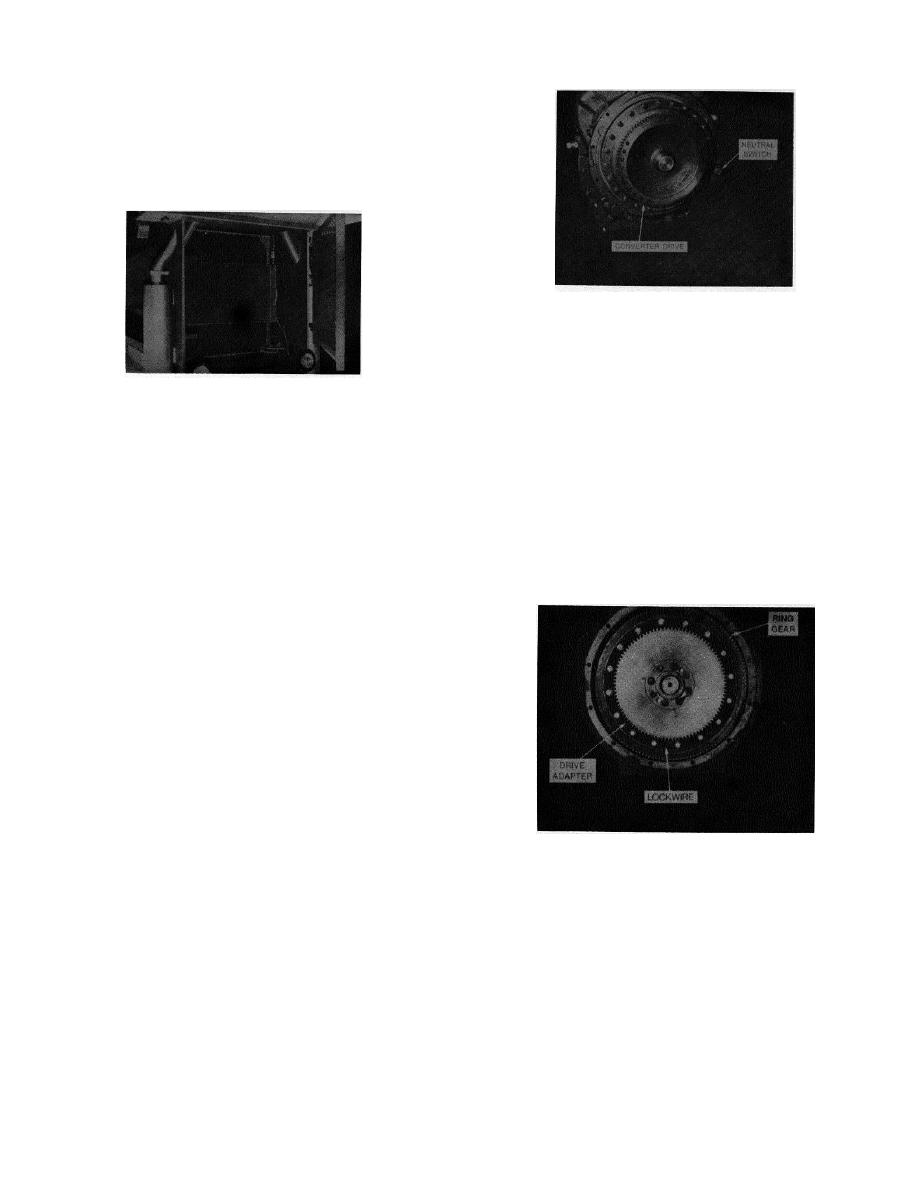

TRANSMISSION

10. Remove front and rear steering cylinder

pins and move both steering cylinders against the side

of the frame.

11. Disconnect and cap the transmission cooler

hoses at the transmission swivel fittings.

Transmission

INSTALLATION:

1.

Reverse procedure for installation. Care

must be taken when coupling the engine to the

Transmission Oil Cooler Connections

transmission, not to damage the fibre ring gear on

engine flywheel.

12. Disconnect and cap hydraulic brake line at

the transmission.

2.

If installing a new ring gear on the engine

flywheel, check to see that it fits on the converter drive

13. Drain the transmission fluid and remove

ring before mounting.

dipstick assembly.

3.

Mount the fibre ring gear on engine

14. Install a suitable lifting device on the engine

flywheel, install bolts and torque evenly to 21 ft-lbs (3 m-

and transmission and support the weight.

kg).

15. Remove front and rear mounting bolts and

lift engine-transmission assembly. When assembly has

been lifted, it must be moved approximately 3" (8 cm)

toward the rear of the frame to allow rear mounting

brackets to clear frame when it is lifted out.

16. After removing assembly from the frame, it

must be positioned on a stand. The transmission can be

separated from the engine by removing the right and left

side mount plates and bolts securing the transmission to

the engine flywheel housing.

Caution: When engine and transmission are being

separated, both units must be supported securely.

Engine

Rev. 760501

50-2.4

K300

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |