|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

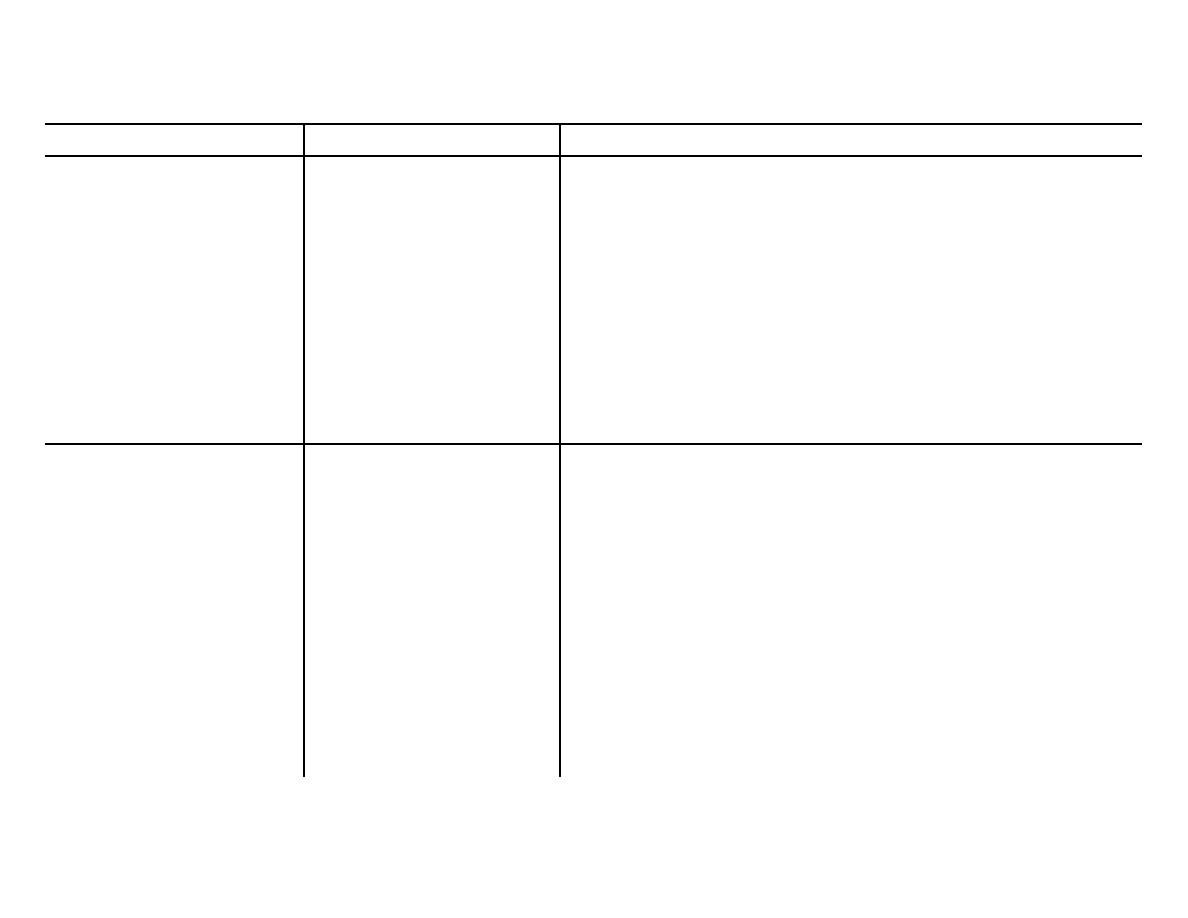

TROUBLESHOOTING

TESTING AND ADJUSTMENT

Problem

Cause

Correction

4. SUDDEN CHANGES IN

Air In The Fuel System

Find the air leak in the fuel system and correct it. Loosen each fuel line nut at the

ENGINE RPM

injection pumps and open the manual bleed valve. Loosen the bolts that hold the

torque spring or stop bar cover. This will let out any air that is in the governor

housing. After all air is out of fuel system, tighten bolts that hold torque spring or

stop bar cover. Tighten fuel line nuts according to the SPECIFICATIONS. Close

manual bleed valve.

Broken Torsion Spring on Sleeve

Install new parts as needed.

Control Shaft

Linkage In Governor Does Not

Clean all linkage and inside of governor housing. Install new parts for those parts

Move Freely

that have damage

Governor Springs Not Completely

Put springs completely on spring seat.

on Spring Seat

Spring for Dashpot Governor

Install spring correctly.

Installed Wrong

5.

NOT ENOUGH POWER

Bad Quality Fuel

Remove the fuel from the fuel tank. Install a new fuel filter element. Put a good

grade of clean fuel in the fuel tank.

Fuel Pressure is Low

Make sure there is fuel in the fuel tank. Look for leaks or bad bends in the fuel line

between fuel tank and fuel transfer pump. Look for air in the fuel system. Check

fuel pressure. The outlet pressure of the fuel transfer pump at full load speed is 30

5 psi (2.1 0.4 kg/cm2 ).

If fuel pressure is lower than above pressure, install a new fuel filter element.

Inspect the fuel bypass valve for free movement. Install a new fuel bypass valve if

necessary.

Find the air leak in the fuel system and correct it. Loosen each fuel line nut at the

Air In The Fuel System

injection pumps and open the manual bleed valve. Loosen the bolts that hold the

torque spring or stop bar cover. This will let out any air that is in the governor

housing. After all air is out of fuel system, tighten bolts that hold torque spring or

stop bar cover. Tighten fuel line nuts according to the SPECIFICATIONS. Close

manual bleed valve.

Leaks in Air Inlet System

Check the pressure in the air intake manifold. Look for restrictions in the air cleaner.

Wrong Fuel Setting

Make adjustments as necessary.

35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |