|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 3-4240-302-30&P-6

Section II TROUBLESHOOTING

2-4. SCOPE. This section provides information for

example, if you have a good airflow valve, you perform

locating and correcting problems in the collective

only the functional checkout (yes path). If the airflow

protection equipment. Use the following flow charts to

valve is defective (no path), the procedure directs you

isolate component problems and to locate repair

step-by-step to locate a defective component or a wiring

instructions.

problem. After module repair, you repeat the functional

checkout at the point in the troubleshooting procedure

This

where you originally dropped out.

The following

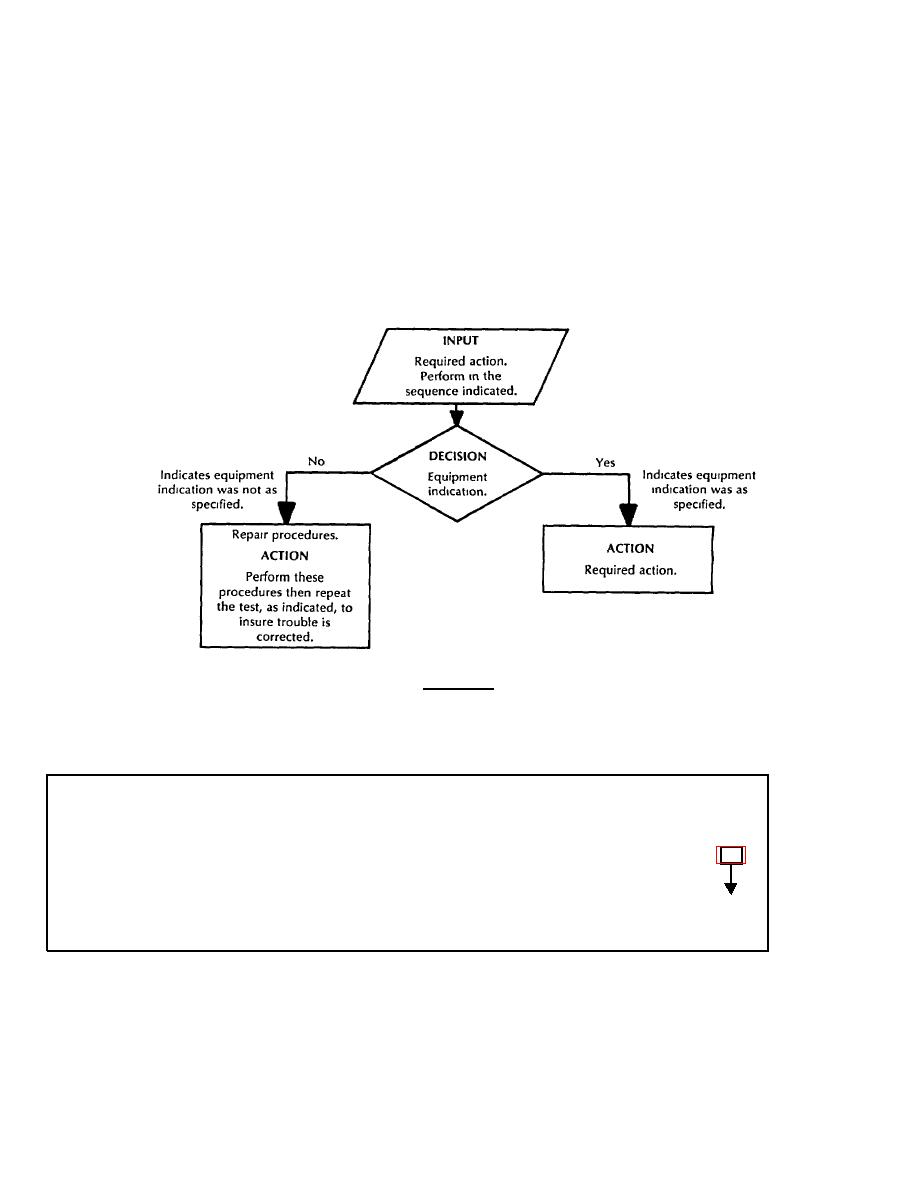

2-5.

FLOW CHART PROCEDURES.

troubleshooting procedure is set up so that you actually

describes the troubleshooting chart symbols.

are performing a module functional checkout.

For

WARNING

High voltage is used to power this equipment. Before removing or installing power

cable, be sure that POWER switch on control module is set to OFF and power

source is shutdown to avoid personal injury or loss of life.

INDEX

PAGE

TROUBLESHOOTING PROCEDURE

Airflow Valve ............................................................................................................................. 2-3

TEST EQUIPMENT

Multimeter 6625-01-092-1197

l

Power Supply 6130-00-408-4962 (or equiv)

l

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |