|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 3-1040-276-23

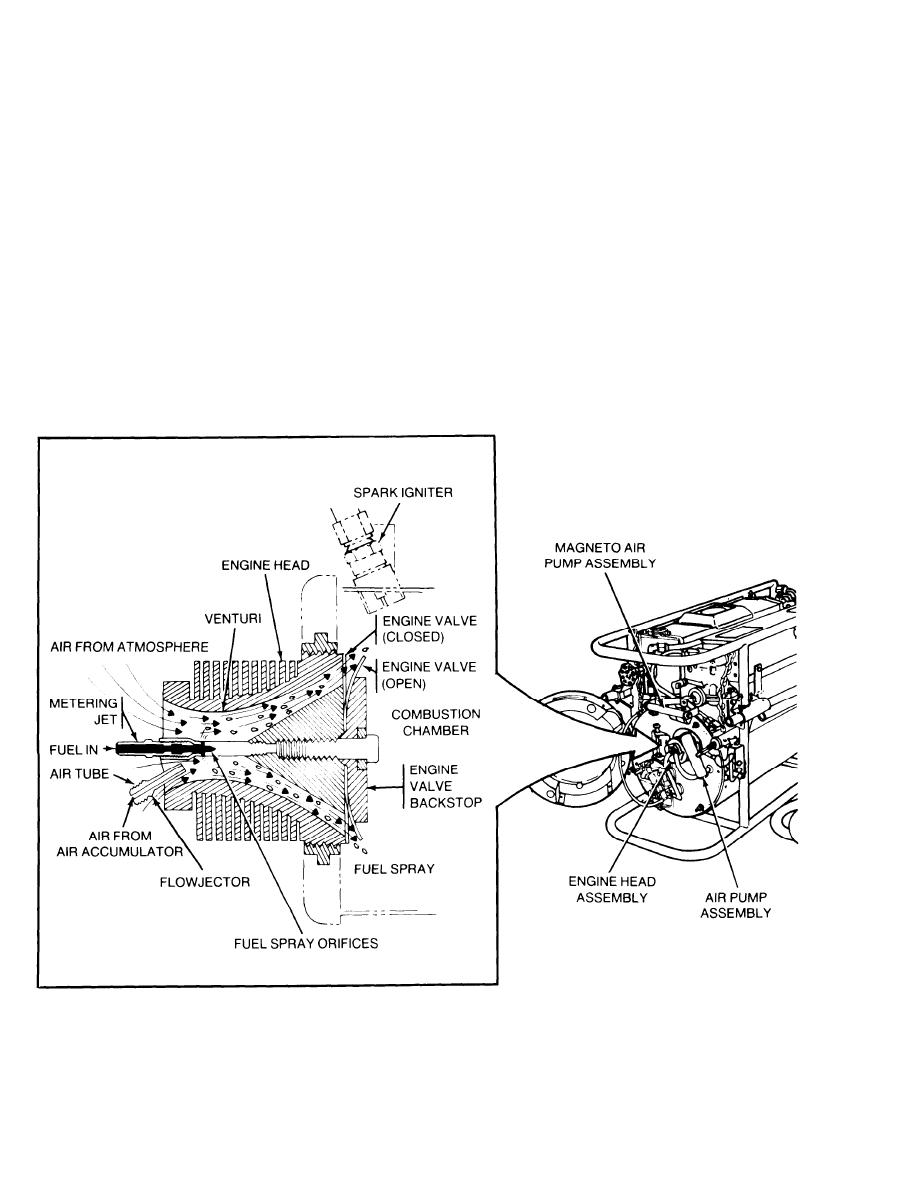

is drawn into air stream past engine valve. Once in

c. Engine Head Assembly. Pulse-jet engine-head

combustion chamber, fuel-air mixture is ignited by hot

and adapter assembly with a metering jet, flowjector,

gases in chamber and cycle begins again without a

and engine valve which is held to rear of engine head by

spark from spark igniter.

an engine valve backstop, washer, and cap screw. Fuel

flows by gravity into metering jet. Air from air accumula-

d. Air Pump Assembly. Hand-operated plunger-

tor passes over three fuel spray orifices in flowjector to

type air pump. Pressurizes air accumulator assembly

draw fuel into engine head venturi. Air pressure opens

which provides pressurized air through air line and air

engine valve as far as engine valve backstop and forces

hose to engine head assembly.

fuel-air mixture into combustion chamber of engine

e. Magneto-Air Pump Assembly. Hand-operated

tube assembly. Spark from spark igniter explodes fuel-

plunger-type air pump and magnetic-electric magneto.

air mixture closing engine valve and forcing burning

Pump handle is connected to rack which engages mag-

gases through engine tube. Shock waves moving

neto gear. Sends electric charge through ignition cable

through engine tube away from engine valve develop

and spark igniter to start engine. Pumps air through air

negative pressure on combustion chamber side of

pump line to purge hot exhaust gases from engine tube

engine valve. This vacuum opens engine valve and

assembly after shut-down of generator.

draws air into combustion chamber. As air from atmo-

sphere passes over fuel spray orifices in flowjector, fuel

1-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |