|

|||

|

|

|||

|

Page Title:

Monthly Preventive Maintenance Checks and Service Charts |

|

||

| ||||||||||

|

|

TM 11-5895-878-14&P

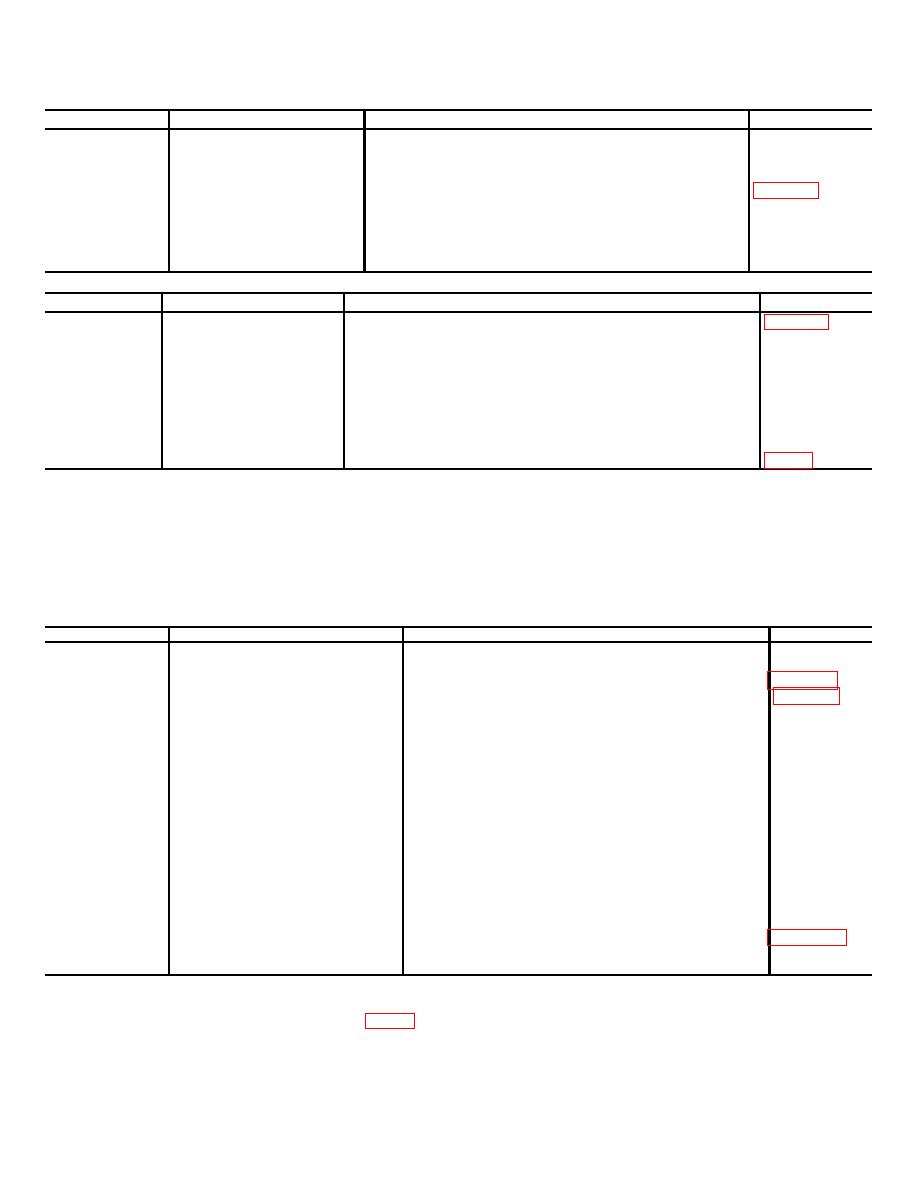

b. Patch and Test Facility (Weekly).

Sequence No.

Item to be inspected

Procedure

References

1

Grounding system.

Verify that the grounding system is properly installed

None.

with good electrical

connections throughout.

2

Cables, wires, and cords.

Remove dirt from cable insulation and connections.

Tighten loose connections at all accessible connectors

and jacks.

3

Lighting system.

Replace defective lamps.

None.

4

Walls, ceilings, and floors. Report any discrepancies to Post Maintenance.

None.

c. Equipment Racks, Equipment, and Power Distribution Panel (Weekly).

Sequence No.

Item to be inspected

Procedure

References

1

Cleanliness.

Remove dirt, dust, and other foreign matter from all

exposed exterior surfaces.

2

Connectors.

Check cables and connectors for secure fit.

None.

3

Mounting.

Check to be sure that the units are securely mounted.

None.

4

Operation.

During normal operation, observe that the mechanical

None.

action of each switch

and control is smooth and free of binding.

5

Lamps.

Check all indicating lamps. Replace defective lamps.

maintenance interval must be made to compensate for

4-6. Monthly Preventive Maintenance

any unusual operating conditions.

Equipment

Checks and Service Charts

maintained in a standby condition must have monthly

Perform the maintenance functions indicated in the

preventive checks and service. Equipment in limited

monthly preventive maintenance checks and service

storage requires services before operation but not daily

chart below once each month. A month is defined as

and weekly preventive maintenance.

approximately 30 calendar days. Adjustment of the

a. Patch and Test Facility (Monthly).

Sequence NO.

Item to be inspected

Procedure

References

1

Grounding system.

Verify the station grounding system is adequately

None.

throughout.

2

Movable parts.

Check all hinges, latches, and metal to metal

sary:

a. Clean and paint bare metal parts.

b. Tighten loose screws, nuts, and bolts.

c. Lubricate.

d. Clean. all air filters.

3

Cables, wires, and cords.

a. Tighten screws, clamps, and nuts that secure

a. None.

b.

Repair insulation cuts and abrasions with

b. None.

tape.

4

Electrical system conduits and

Tighten loose screws, bolts, and clips. Repair or

None.

switches, switchplates, outlets, and receptacles.

5

Equipment mountings.

a. Tighten all loose bolts, nuts, screws, and clamps

None.

equipment racks, frames, shelves, braces, and

ware. Replace missing hardware.

b. Check to see that equipment mounting racks,

None.

braces, and clamps are not bent, broken, or out of

danger equipment or personnel.

6

Fuses.

Check fuses at fuse panel and equipment. Replace

Verify that all operating fuses are of the correct

fuses for proper value and quantity.

Quarterly preventive maintenance checks are required

b. Equipment (Monthly). Perform periodic checks

on the P&T. Periodic, daily, weekly and monthly

and services on each equipment in the facility (App A).

services constitute a part of the quarterly preventive

maintenance checks and services and must be

4-7. Quarterly Preventive Maintenance

performed concurrently. All deficiencies will be recorded

Checks and Service Charts

and corrected.

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |