|

|||

|

|

|||

|

Page Title:

USING ENGINE TO RECOVER FIELD WIRE OR CABLE |

|

||

| ||||||||||

|

|

TM 11-3895-209-14

2-8. USING ENGINE TO RECOVER FIELD WIRE OR CABLE

The RL-207(*)/G will accommodate two RL-159/U's, one DR-5 or one DR-15 per axle. The upper or

lower axle may be used individually or both axles may be used simultaneously. To recover wire or

cable proceed as described below.

Install the required number of empty reels on the axles. Secure the end of the wire or cable to be

recovered to each reel.

WARNING

Oil and gasoline are used in the RL-207(*)/G. Do not smoke when adding or draining fuel.

Check to be sure that the fuel tank is full and that the proper amount of oil is in the engine

Start the engine as follows:

WARNING

The RL-207(*)/G constitutes a noise hazard while in operation. Hearing protection is

required when either machine is operated for more than 1 hour per day. Failure to use

hearing protection may result in temporary or permanemt hearing loss.

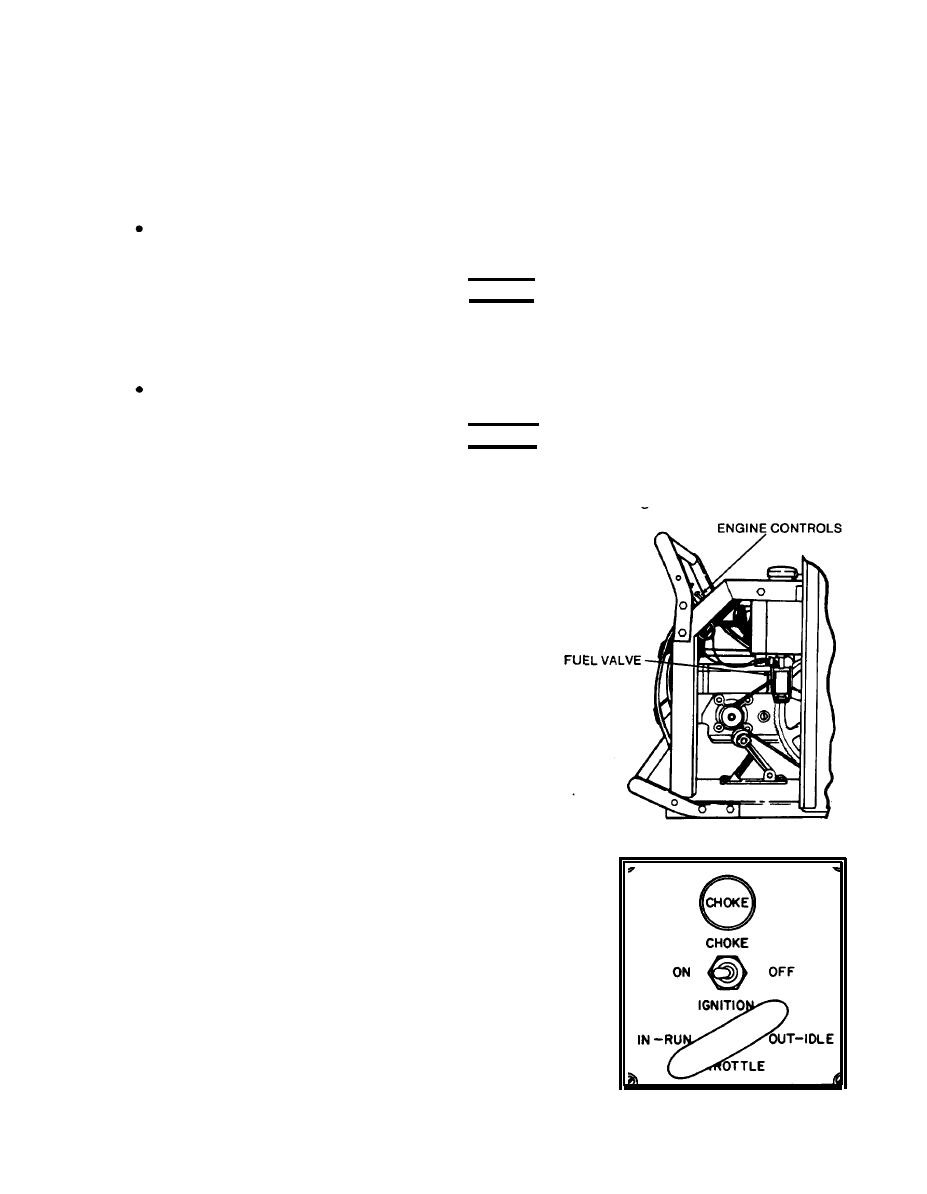

A Turn the fuel valve fully counterclockwise (on).

B If the engine is cold, pull the CHOKE control fully out.

If the engine is hot, leave the CHOKE control in.

c Turn the THROITLE control counterclockwise and

pull it about halfway out. Lock the THROITLE control

by turning it clockwise.

D Operate the IGNITION switch to ON.

E Wind the starter cord around the engine pulley and

pull sharply on the starter cord until the engine starts.

F Allow the engine to warm up for at least 1 minute.

Adjust the CHOKE control, as required, during the

warm-up period to maintain smooth engine operation.

. To recover field wire or cable:

A Turn the THROITLE control counterclockwise and

push it inward until the motor is running at the desired

speed. Turn the THROITLE control clockwise to

secure it in the desired position.

B Operate the control lever associated with the reel

being used to the run (forward) position to cause the

reels to turn. Control the axle speed (reel speed) by

varying the pressure on the control levers.

C Guide the wire or cable onto the reel to be sure that it

is wound in in smooth level layers acoss the reel.

Maintain enough tension on the wire or cable to

ensure that it is wound tightly on the reel.

2-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |