|

|||

|

|

|||

|

Page Title:

LIFT THICKNESS / NUMBER OF PASSES: |

|

||

| ||||||||||

|

|

COMPACTION:

densities from being attained and the moisture content

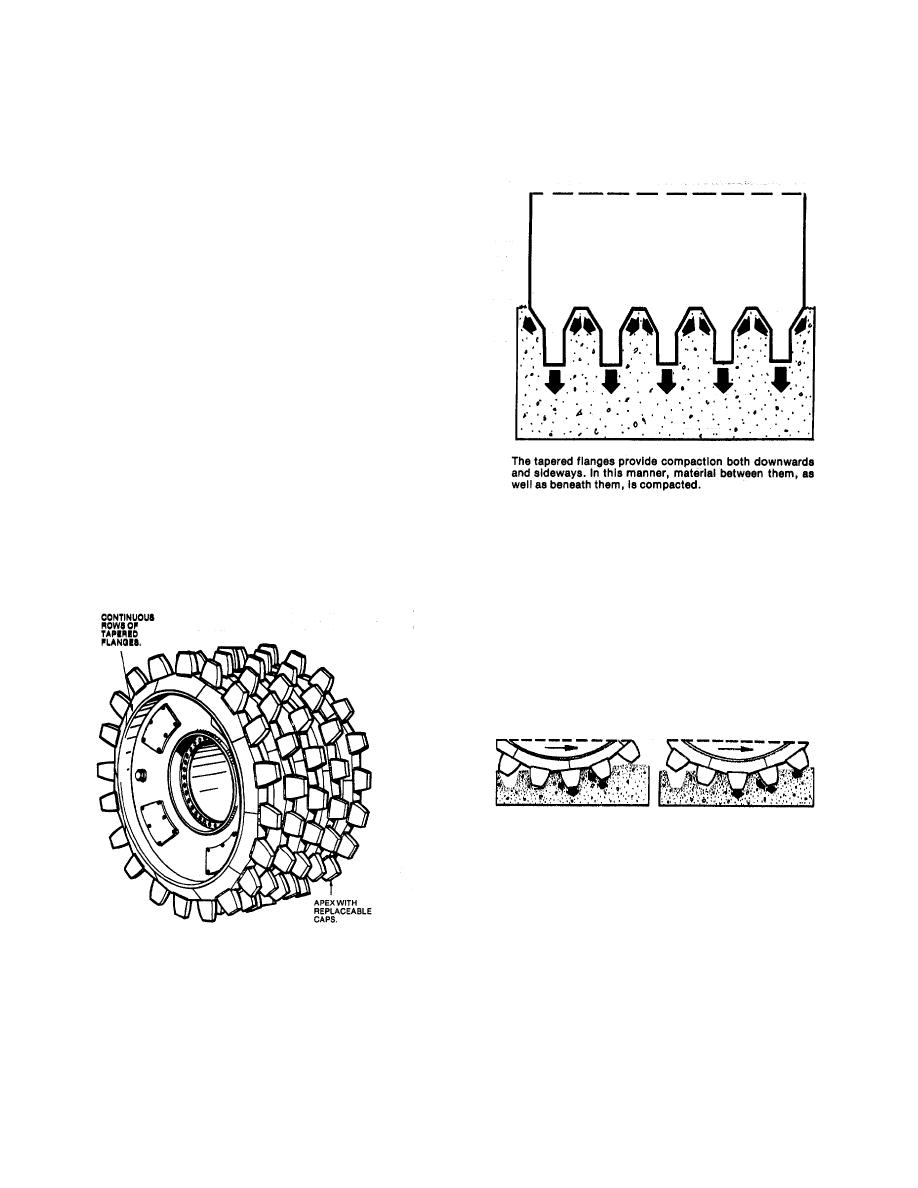

Responsible for this versatility is the shape of the wheel

may have to be reduced by aeration prior to compaction.

flanges. The tapered edges of these flanges exert pressure

laterally as well as downward, allowing the machine to "walk

out" in fewer passes.

LIFT THICKNESS / NUMBER OF PASSES:

The greatest increases in density occur within the initial

five passes, depending upon soil and field conditions.

Additional passes may produce only slight gains, or even

be detrimental. Generally, the lift thickness varies from 6

to 12 Inches (15 to 30 cm), depending upon conditions.

While there are no set rules, we would recommend

starting with a 6" (15 cm) lift and plotting achieved

densities versus the number of passes. Increase the

depth of lift in three inch (7,6 cm) Increments until you

find the optimum combination of lift thickness and number

of passes for the particular conditions. Care should be

exercised in compaction to avoid selecting such a deep

lift that bridging of the bottom of the lift occurs. When the

proper combination has been determined, one must be on

the lookout for changes In soil type and moisture content.

If proper control is maintained, consistent compaction

throughout the Job will be achieved.

COMPACTION / MACHINE OPERATION:

Segmented compaction wheels produce higher surface

pressures and exert a combination of Impact and

kneading action on the soil. The BOMAG K300 Pakall

wheels provide great versatility In soil compaction. Soils

ranging from sandy loams to heavy clay may be com-

pacted with relative ease.

As the wheel sinks Into uncompacted soil, the tapered

flanges offer a large amount of bearing area to prevent

over-stressing the soil when there Is low shear resistance.

As soil density Increases, the wheel begins to "walk out",

riding progressively higher on the wheel flanges,

concentrating the compactive force on Its narrow ridges and

finally on the apexes.

As the flanges turn, they penetrate the loose soil. Pressure

is at first exerted both angularly on the leading load-bearing

surface and downward on the trailing load-bearing surface.

The compactor's full weight is applied downward when the

apex reaches Its point of deepest penetration. When, upon

further rotation, the apex is withdrawn, the compacted soil is

left undisturbed. Shearing is kept to a minimum.

Rev. 760501

K300

300-1.2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |