|

|||

|

|

|||

|

Page Title:

PRESSURE BLEEDING INSTRUCTIONS: |

|

||

| ||||||||||

|

|

BRAKE CONTROL:

valve assembly into the end nut and screw the end nut

tightly into the master brake cylinder.

Note: It is very important that the end nut be drawn in

tightly.

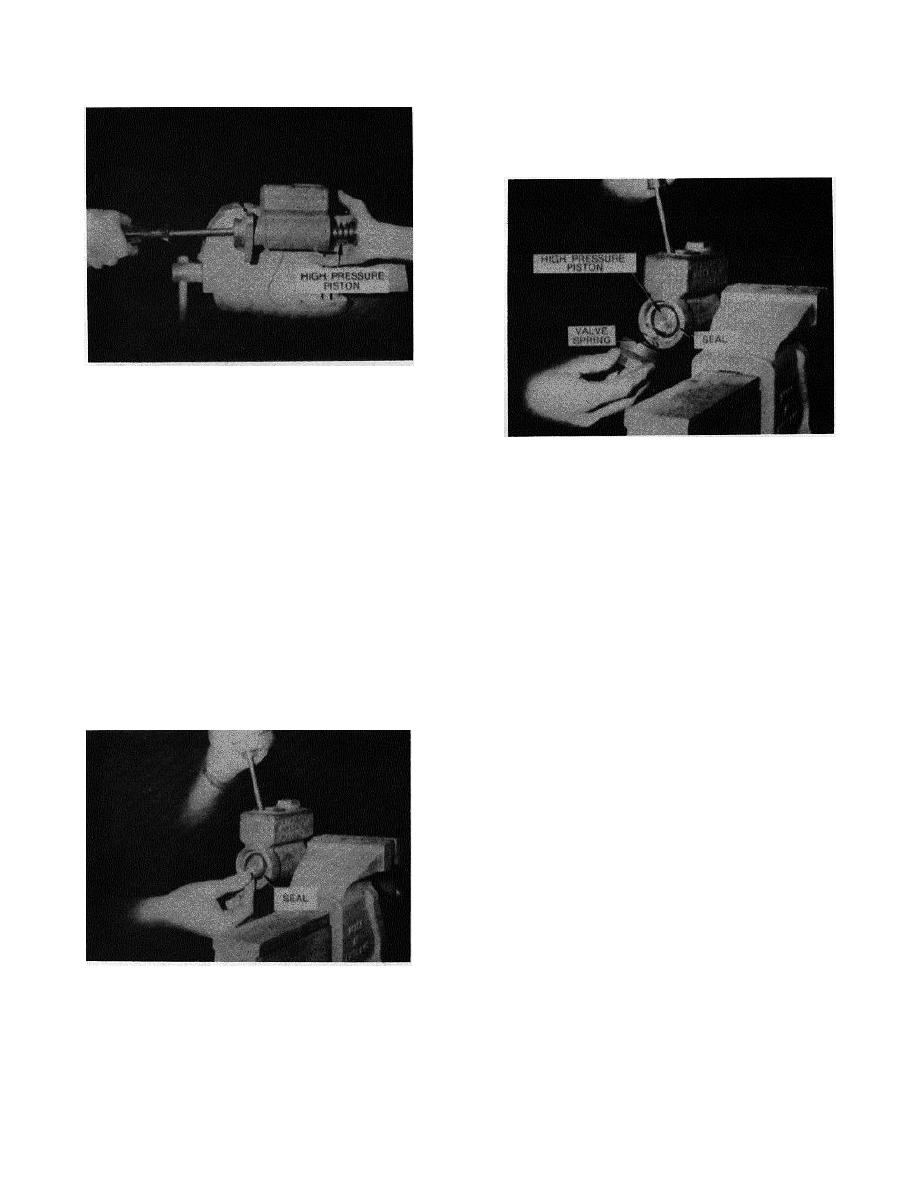

High Pressure Piston Installation

6. While holding the low pressure piston in position,

enter high pressure cup into the low pressure piston. At

this time, force the piston into the cylinder so that the

End Plug Installation

base of the high pressure piston seals on the inside

gasket. This operation will have to be performed under

PRESSURE BLEEDING INSTRUCTIONS:

spring pressure because it is necessary to hold the low

1. Pressure bleeding is performed when master

pressure piston forward in order to ensure proper entry of

brake cylinder is mounted on machine and fully

the cup.

connected. There must be at least 1/32 inch (1 mm) play

7. Release the pressure of the screwdriver or rod

between power cylinder piston and pushrod.

against the pushrod end and at the same time apply

2. Fill reservoir with proper transmission fluid (refer

enough pressure against the base of the high pressure

to LUBRICANTS SPECIFICATION CHART).

piston so as to prevent the high pressure cup from coming

3. Check that all fittings are tight to avoid leakage.

out of the high pressure cylinder.

4. Open bleeder screw on transmission brake,

8. Insert a rod or screwdriver into the relief valve

depress brake pedal and hold'.

opening and pry it sideways against the high pressure

5. Tighten bleeder screw and release pedal. Repeat

piston with enough force to prevent the assembled parts

until all air is removed.

from moving out of position.

6. Recheck

brake

cylinder

fluid

level.

9. While holding the parts in position with the rod or

screwdriver, replace the outside gasket and rubber seal.

Place the retarding

Rev. 760501

K300

70-1.4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |