|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

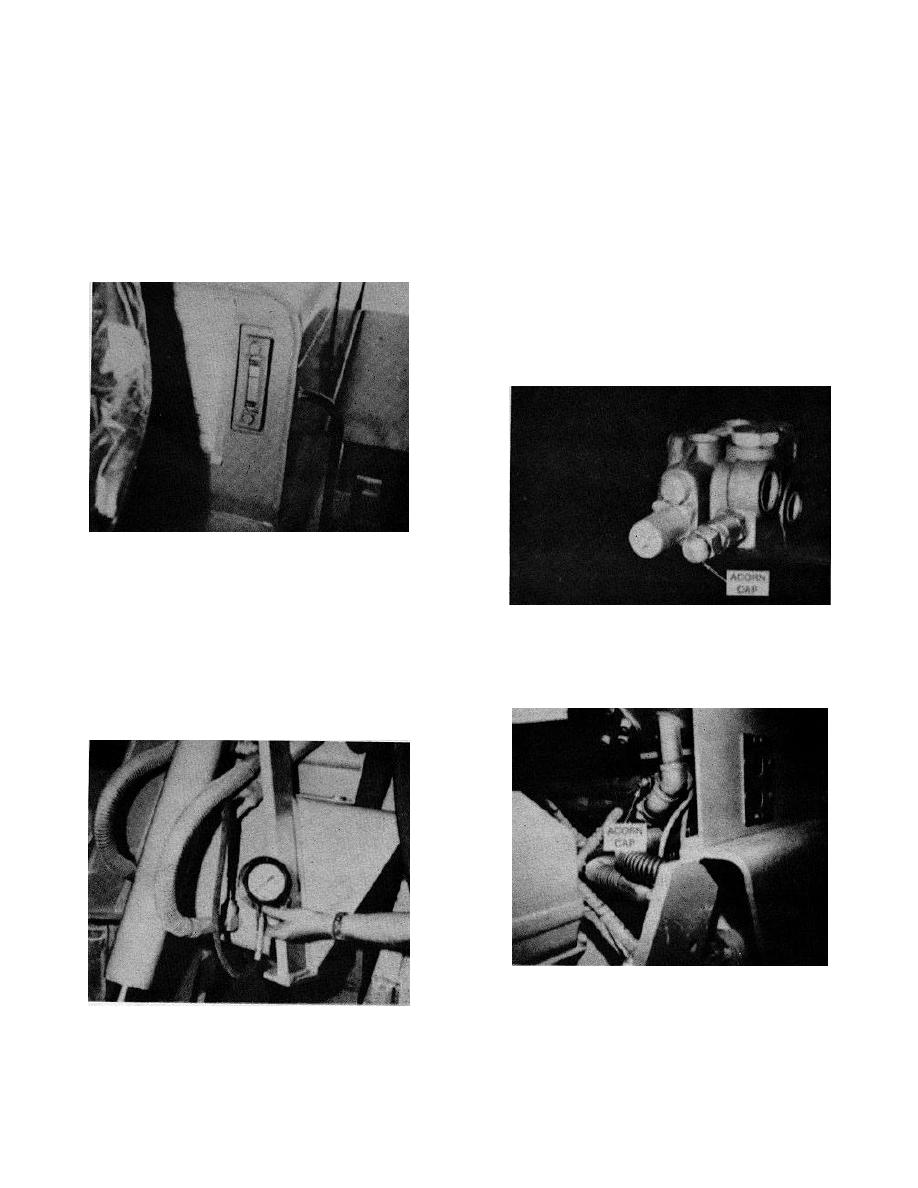

HYDRAULIC SYSTEM

MAINTENANCE:

1. Install a 3000 psi (20,000 kPa/200 kg sq/ cm)

pressure gauge in dozer hydraulic system test port on

CHECK HYDRAULIC TANK OIL LEVEL daily with

front frame bulkhead at dozer cylinder hose.

machine level, blade lowered and engine off. The level

gauge is mounted on the forward surface of the hydraulic

2. With engine RPM at 2000, check relief valve

tank on the operator's left. Add the proper fluid as

pressure by raising dozer blade to maximum height and

necessary (refer to LUBRICANTS SPECIFICATION

taking gauge reading.

CHART).

Caution: Do not hold for more than 30 seconds.

3. If pressure is more than 50 psi (345 kPa/3,5

kg/sq. cm.) above or below 1500 psi (J0335 kPa/106

kg/sq cm), the relief valve should be adjusted.

Hydraulic Oil Level Gauge

CHECK ALL HOSES AND CONNECTIONS every 50

hours for leaks, correcting where necessary. Damaged

hoses should be replaced immediately.

4. Remove acorn cap on relief valve.

DOZER SYSTEM PRESSURE:

5. Loosen jam nut.

6. Turn adjusting screw one quarter turn at a time, in

TESTING AND ADJUSTMENT should be made every

to raise pressure, or out to lower pressure.

400 hours after machine operation with hydraulic oil at

operating temperature.

Dozer ReIief Adjustment

Dozer System Pressure Test

Rev.760501

K300

60-1.1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |