|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

AXLES:

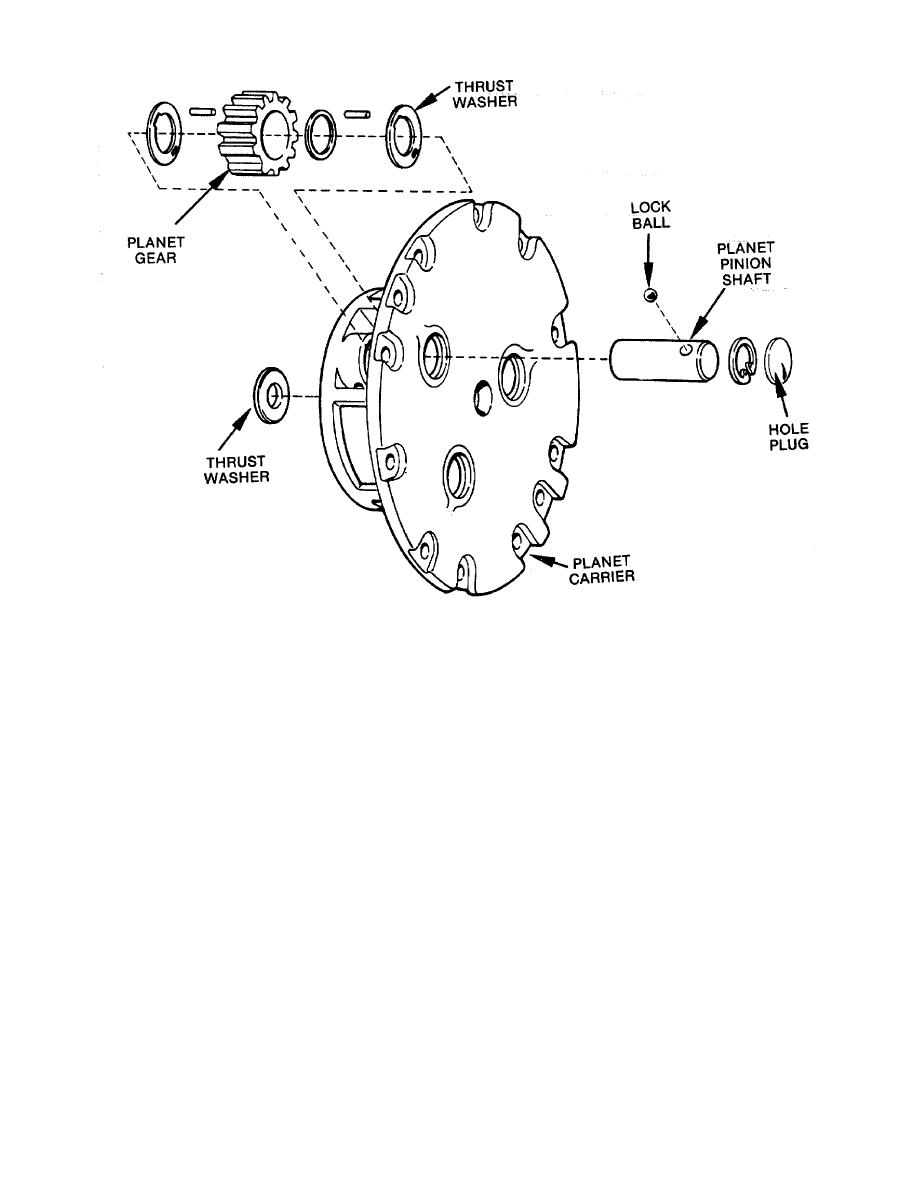

Planetary Carrier Assembly

5.

Install wheel bearing adjusting nut. While

DRIVE AXLE REASSEMBLY:

tightening nut, rotate wheel hub, and rap with a rubber or

1.

Being certain housing face is clean, apply

rawhide mallet until a definite drag is felt. Install sun gear

Permatex No. 2 and install differential and carrier in

thrust washer and adjust wheel bearing preload.

housing,

securing in place on housing studs and

6.

Use Permatex No. 2 on face of wheel hub and

tightening nuts to specified torque (refer to TORQUE

install a new O ring when installing planet spider

SPECIFICATIONS CHART).

assembly in position. Secure In place with special

2.

If spindle ends have been removed from

capscrews and lockwashers provided.

Tighten to

housing, secure in place with special bolts, nuts and

specified torque (refer to TORQUE SPECIFICATIONS

washers provided. Tighten to specified torque (refer to

CHART).

TORQUE SPECIFICATIONS CHART).

7.

Assemble sun gear in place on axle shaft and

3.

Install inner and outer hub bearing cups into

place retaining ring in position in groove on shaft.

hub assembly. Place inner hub bearing cone in position

8.

Insert splined end of shaft into axle housing,

and install hub oil seal with lip of seal toward bearing. Fill

aligning splines with differential side gear and aligning

oil seal lip with clean grease. Assemble hub on spindle.

gear teeth on sun gear with teeth on planet pinions.

4.

Assemble internal gear into internal gear hub,

9.

Use Permatex No. 2 on face of planet spider

securing in place with special capscrews provided.

and install a new O ring when installing hub thrust cap

Tighten to specified torque (refer to TORQUE

assembly in position. Secure in place with capscrews and

SPECIFICATIONS CHART). Assemble outer hub bearing

lockwashers and tighten to specified torque (refer to

cone in place on internal gear hub and assemble gear,

TORQUE SPECIFICATIONS CHART).

hub and bearing in position on housing.

Rev. 760501

K300

50-3.8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |