|

|||

|

|

|||

|

Page Title:

RESTRICTION OF AIR INLET AND EXHAUST |

|

||

| ||||||||||

|

|

CYLINDER HEAD AND VALVES

TESTING AND ADJUSTING

CYLINDER HEAD AND VALVES

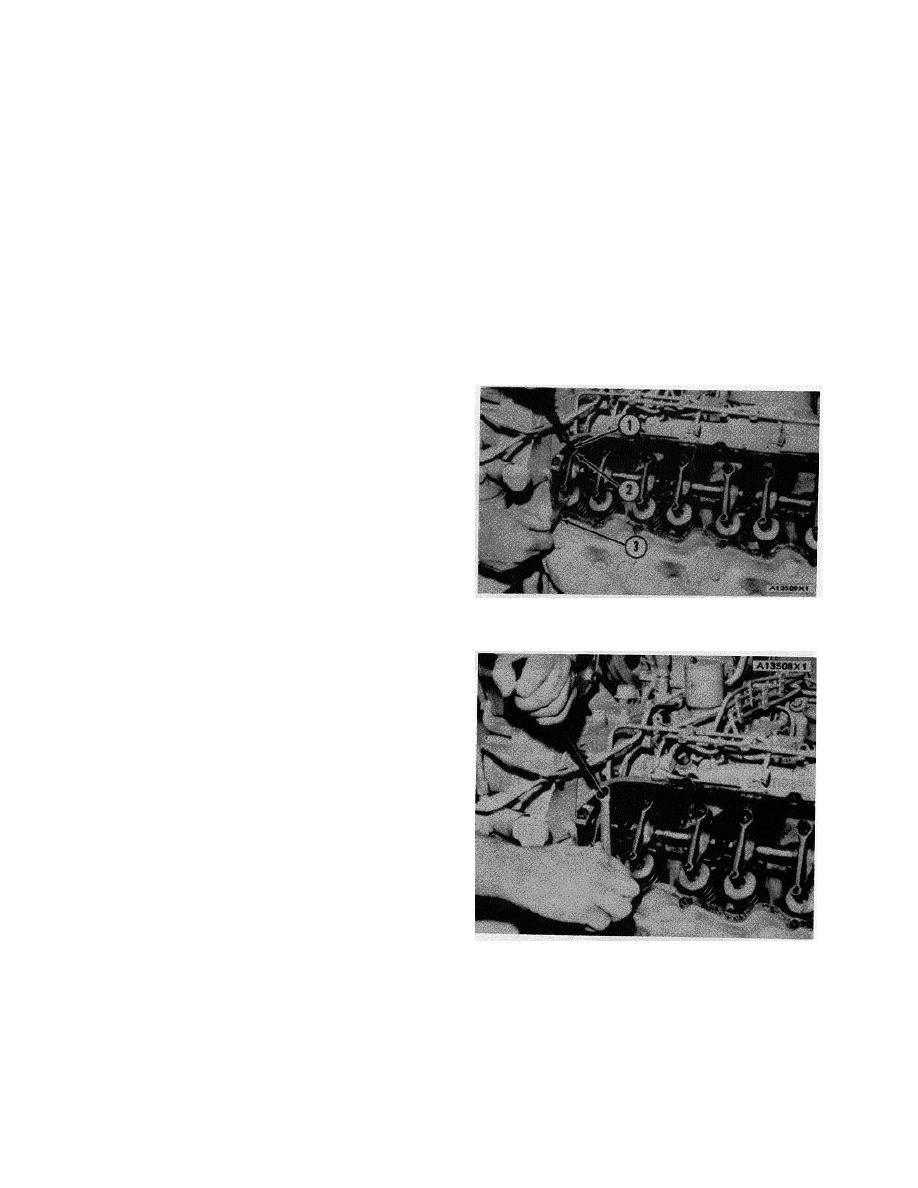

3. Make adjustment to the valves for No.1 and No.2

RESTRICTION OF AIR INLET AND EXHAUST

cylinders. To make the adjustment, loosen

locknut (2). Turn the adjustment screw (1) until

There will be a reduction of horsepower and efficiency

the feeler gauge (3) will go between the end of

of the engine if there is a restriction in the air inlet or

the valve stem and the rocker arm.

exhaust system.

NOTE: Use a . 015 in. (0.38 mm) feeler gauge for the

Air flow through the air cleaner must not have a

intake valves. Use a .025 in. (0.64 mm) feeler gauge for

restriction of more than 25 in. (635 mm) of water

the exhaust valves.

difference in pressure.

4. After the adjustment is complete, hold adjustment

Back pressure from the exhaust (pressure difference

screw (1) and tighten locknut (2) to 24 5 lb. ft.

measurement between exhaust outlet elbow and

(3.3 0.7 mkg). After the locknut is tightened,

atmosphere) must not be more than 34 in. (864 mm) of

check the adjustment again.

water.

COMPRESSION

An engine that runs rough can have a leak at the

valves, or valves that need adjustment. Run the engine at

the speed that gives rough running. To find a cylinder that

has low compression or does not have good fuel ignition,

loosen a fuel line nut at a fuel injection pump. This will

stop the flow of fuel to that cylinder. Do this for each

cylinder until a loosened fuel line is found that makes no

difference in engine rough running. Be sure to tighten

each fuel line nut after the test before the next fuel line

nut is loosened. This test can also be an indication that

the fuel injection is wrong, so more checking of the

VALVE LASH ADJUSTMENT

cylinder will be needed. This test is just a fast method of

1. Adjustment screw. 2. Locknut. 3. Feeler gauge.

finding the cause of compression loss in a cylinder.

Removal of the head and inspection of the valves and

valve seats is necessary to find those small defects that

do not normally cause a problem. Repair of these prob-

lems is normally done when reconditioning (overhaul) the

engine.

CHECKING ADJUSTMENT OF THE

VALVE LASH

Check the adjustment of the valve lash during the first

80 hours of operation and every 500 hours of operation

after the first adjustment. If the engine is not used for 500

hours in six months, check the adjustment of the valve

lash after every six months.

To check and make adjustment to the valve lash, use

the following procedure:

TIGHTENING LOCKNUT

1. Remove the valve covers.

5. Turn he crankshaft 180 CLOCKWISE (as seen

from. front of engine ). The VS mark on the

2. Turn the crankshaft CLOCKWISE (as seen from

damper assembly will be in alignment with the

front of engine) until No.1 piston is at top center

tighting pointer. Make adjustment to the valves

on the compression stroke. The TDC-1 mark on

for No.3 and N.7 cylinders.

the damper assembly will be in alignment with the

timing pointer.

70

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |