|

|||

|

|

|||

|

Page Title:

GOVERNOR ADJUSTMENTS |

|

||

| ||||||||||

|

|

FUEL SYSTEM

TESTING AND ADJUSTMENT

b. With wrench (8) in the screw for lever (12) and

dial indicator held tightly on top of the calibration

pump, use wrench (8) to move lever (12) up or

down until the dimension on the dial indicator is

zero. Tighten the screw to 24 2 lb. in. (27.7

2.3 cm. kg).

c.

After the screw is tightened, use the dial indicator

to check the adjustment again.

13. The calibration of each pump can be checked using

this same procedure. The 1P7379 Microgage is used

to put the dial indicator on zero before the calibration

dimension of each pump is checked.

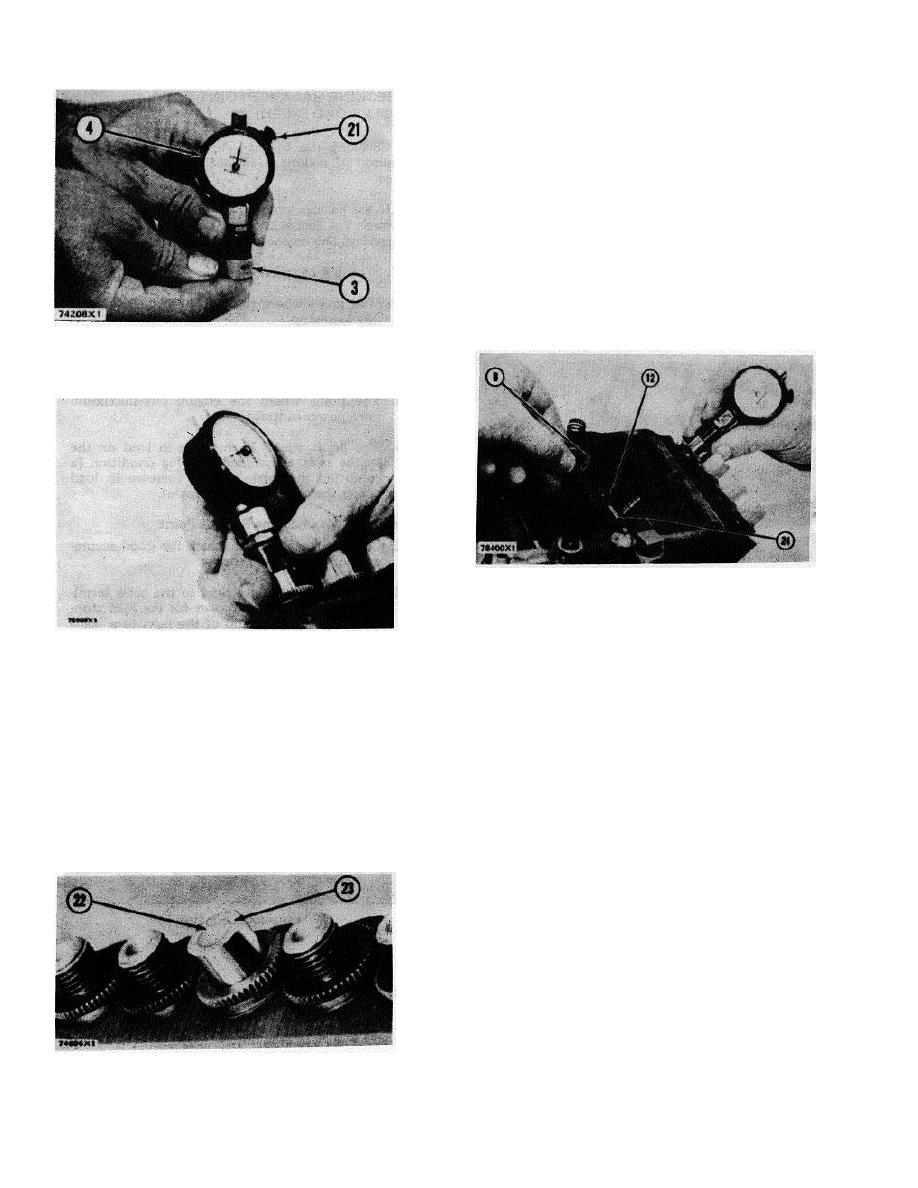

PUTTING DIAL INDICATOR ON ZERO

3. 1P7379 Microgage. 4. 3P1568 Indicator with 3P2226

Base. 21. Lockscrew.

CALIBRATION OF AN INJECTION PUMP

8. 1S9836 Wrench. 12. Lever. 24. Sleeve control shaft.

CHECKING PUMP CALIBRATION

14. If a pump is checked and an adjustment is made,

again check the dimension after the lever screw is

12. If a pump needs to be calibrated, use the following

tightened.

procedure:

a. Use wrench (8) to loosen the screw that holds

GOVERNOR ADJUSTMENTS

lever (12) on shaft (24). Loosen the screw just

enough so lever (12) can be moved (up or down)

CAUTION: A mechanic that has the correct training is the

on shaft (24).

only one to make the adjustment of low idle and high idle

rpm. The correct low idle and high idle rpm, and the

NOTE: Move the lever and put plunger (22) of the

measurements for adjustment of fuel setting are given in

calibration pump almost flush with top surface (23) of the

the RACK SETTING INFORMATION.

calibration pump.

Check engine rpm with a tachometer that has good

accuracy. If the low idle or high idle rpm needs an

adjustment, use the following procedure:

1. For adjustment of low idle, loosen locknut (2) and turn

adjustment bolt (1) to get as near as possible to the

correct low idle rpm.

2. After the low idle adjustment is correct, tighten

locknut (2).

POSITION OF PLUNGER

22. Plunger. 23. Top surface of calibration pump.

63

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |