|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

FUEL SYSTEM

TESTING AND ADJUSTMENT

FUEL INJECTION LINES

Fuel from the fuel injection pumps is sent through the

fuel injection lines to the fuel injection nozzles.

Each fuel injection line of an engine has a special

design and must be installed in a certain location. When

fuel injection lines are removed from an engine, put

identification marks or tags on the fuel lines as they are

removed, so they can be put in the correct location when

they are installed.

The nuts that hold a fuel injection line to an injection

nozzle and injection pump must be kept tight. Use a

torque wrench and the 5P144 Fuel Line Socket to tighten

the fuel line nuts to 30 5 lb. ft. (4.1 0.7 mkg).

FUEL INJECTION PUMPS

When injection pumps, sleeves and lifters are removed

from the injection pump housing, keep the parts of each

pump together so they can be installed back in their

original location.

Be careful when disassembling injection pumps. Do not

damage the surface on the plunger. The plunger, sleeve

and barrel for each pump are made as a set. Do not put

the plunger of one pump in the barrel or sleeve of another

pump. If one part is worn, install a complete new pump

assembly. Be careful when putting the plunger in the bore

of the barrel or sleeve.

Return Leakage Test

When an injection pump is installed correctly, the

plunger is through the sleeve and the adjustment lever is

1. Put the tip of the fuel injection nozzle a little above the

engaged with the groove on the sleeve. The bushing that

horizontal position. Tighten the nuts that connect the fuel

holds the injection pump in the pump housing must be kept

injection nozzle to the tester.

tight. Tighten the bushing to 70 5 lb. ft. (9.7 0.7 mkg).

Damage to the housing will result if the bushing is too tight.

2. Operate the tester until the pressure is at 1400 to 1600

If the bushing is not tight enough, the pump will leak.

psi (98.4 to 112.5 kg/cm2 ).

3. Look at the leakage from the return at the top (pressure

screw end) of the fuel injection nozzle. After the' first two

drops fall, leakage is 1 to 10 drops in 15 seconds with Kent

Moore J23300-585 or Shell 66631 calibration oil or

equivalent, with the temperature of the calibration oil at

650 to 765 F (180 to 240 C). More than 10 drops in 15

seconds is an indication of parts with wear or bad parts,

and replacement of the fuel injection nozzle is necessary.

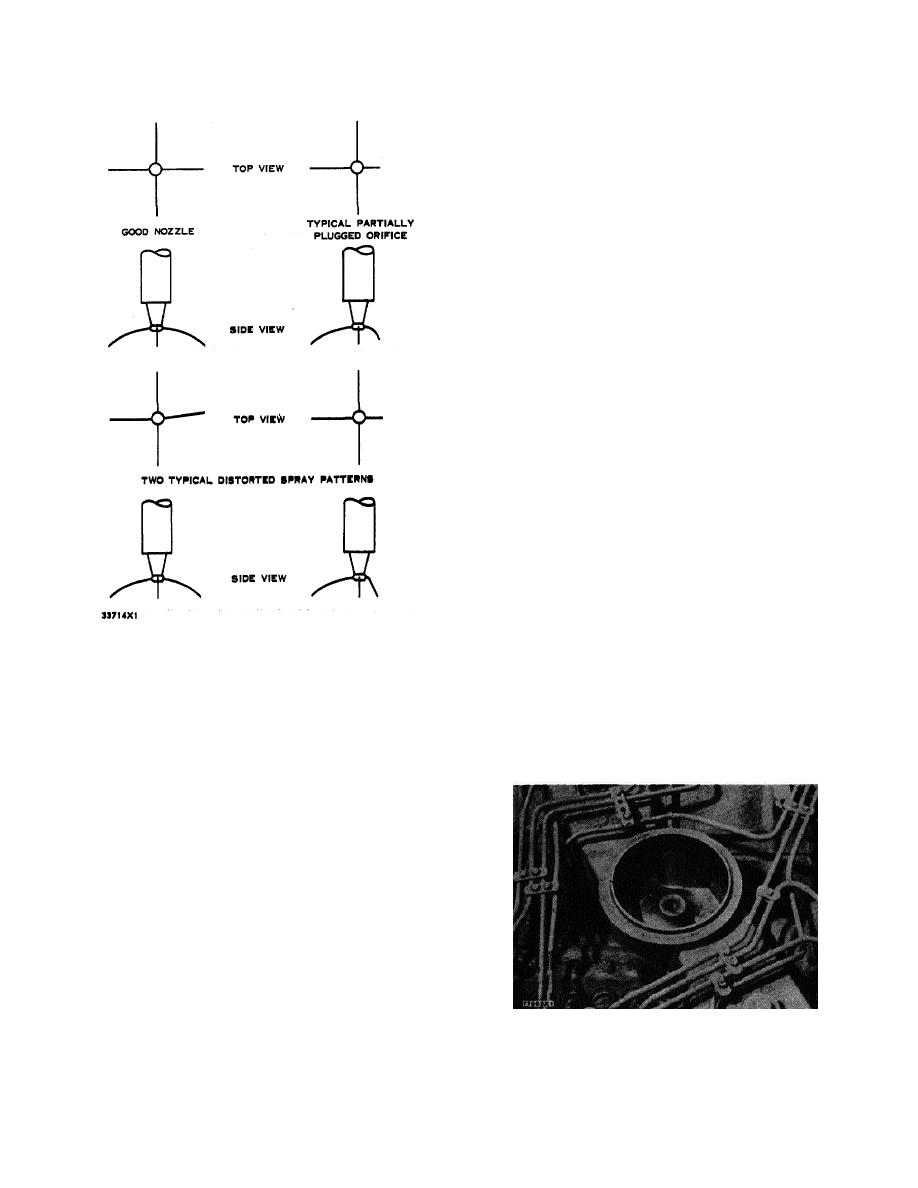

NOZZLE ASSEMBLY TROUBLESHOOTING GUIDE

For

the

NOZZLE

ASSEMBLY

AIR INLET PIPE

TROUBLESHOOTING GUIDE, See Page 49.

(Typical Example)

53

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |