|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

FUEL SYSTEM

TESTING AND ADJUSTMENT

the 8S2258 Brass Wire Brush. A change in color in the

area below the groove is normal and does not effect the

body of the nozzle. Remove the carbon, but do not use the

8S2258 Brass Wire Brush to cause damage to the body of

the nozzle. Do all tests before cleaning or making any

adjustments to a nozzle. A test can show that the nozzle

must not be used again.

WARNING: When testing a fuel injection nozzle,

keep the tip of the nozzle pointed away from the

operator and into the 8S2270 Fuel Collector. Fuel

from the orifices in the tip of the nozzle is under high

pressure and can cause injury to the operator.

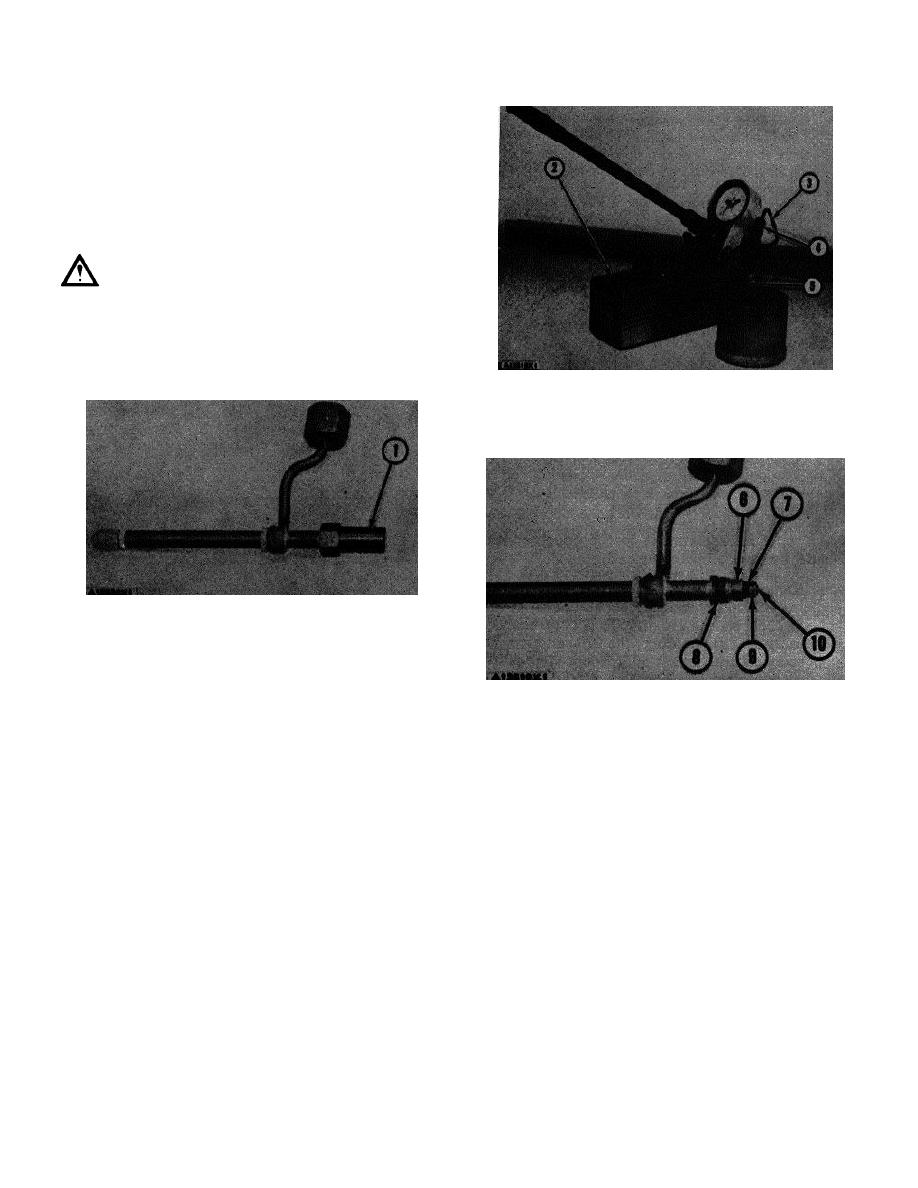

NOTE: Remove cap (1) from the fuel injection nozzle

before putting the nozzle on the 8S2267 Nozzle Tester.

CONNECTING NOZZLE TO TESTER

2. 82257 Nozzle Tester. 3. 8S2268 Tube

Assembly. 4. 9S3093 Adapter. 5. Fuel injection

nozzle.

FULL INJECTION NOZZLE

1. Cap.

Put the fuel injection nozzle (5) to the 8S2267 Nozzle

Tester (2) using the 8S2268 Tube Assembly (3) and the

FULL INJECTION NOZZLE

9S3093 Adapter (4). The nut on the fuel injection nozzle

6. Locknut (for pressure adjustment screw). 7.

can be tightened by hand if the 1 H 1023 Seal does not

Pressure adjustment screw. 8. 0-ring seal. 9.

have damage.

Locknut (for lift adjustment screw). 10. Lift

adjustment screw.

CAUTION: Be sure to use clean SAE J967b oil or Kent-

Moore J23300-585 or Shell 66631 calibration oil when

Opening Pressure Test

testing. Dirty test oil will damage components of the fuel

injection nozzle.

CAUTION: Put a shop towel around the top of the

fuel injection nozzle (pressure screw end) to take

NOTE: Kent-Moore J23300-585 calibration oil can be

in any possible leakage of fuel.

purchased from Kent-Moore C Shell Oil Company.

1. Close the gauge protector valve. Close the on-off

valve. Open the pump isolator valve. Flush the

fuel injection nozzle by operating the nozzle tester

for 10 to 15 strokes at a rate of 60 strokes per

minute.

2. Open the gauge protector valve. Make a slow

increase to the pressure until the valve in the

45

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |