|

|||

|

|

|||

|

Page Title:

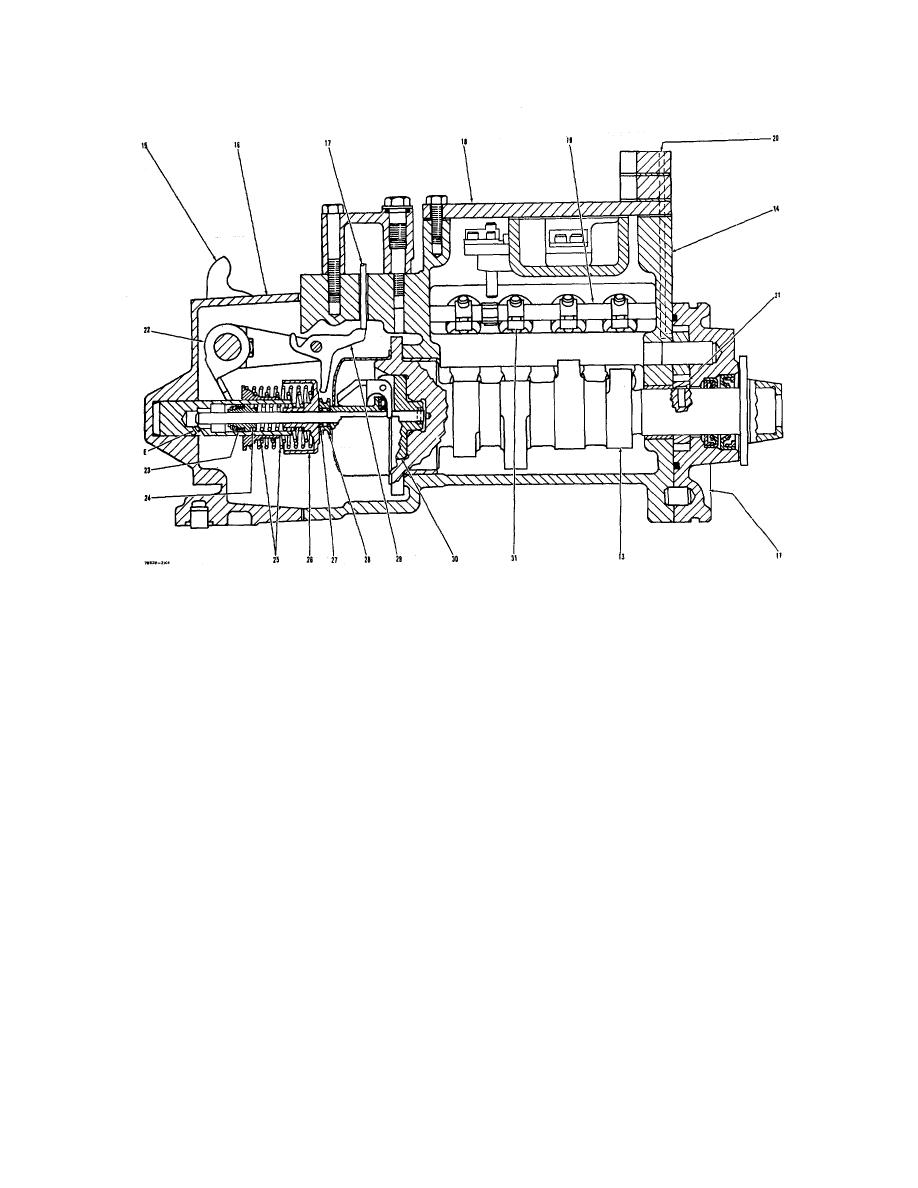

CROSS SECTION OF FUEL SYSTEM WITH DASHPOT GOVERNOR |

|

||

| ||||||||||

|

|

FUEL SYSTEM

SYSTEMS OPERATION

(75V1-UP, 90N6121-UP)

CROSS SECTION OF FUEL SYSTEM WITH DASHPOT GOVERNOR

11. Fuel transfer pump. 13. Camshaft. 14. Housing for fuel injection pumps. 15. Lever. 16. Governor housing. 17. Load stop

pin. 18. Cover. 19. Sleeve control shafts {(two). 20. Inside fuel passage.'21. Drive gear for fuel transfer pump. 22. Lever on

governor shaft. 23. Piston for dashpot governor. 24. Spring for dashpot governor. 25. Governor springs (inner spring is for low

idle: outer spring is for high idle). 26. Spring seat. 27. Over fueling spring. 28. Thrust collar. 29. Load stop lever. 30. Carrier

and governor weights. 31. Sleeve levers. E. Orifice for dashpot.

From fuel transfer pump (11), fuel under

in compression and move thrust collar (28) for-

pressure, fills the housing for the fuel injection

ward. As thrust collar (28) moves forward, the

pumps (14). Pressure of the fuel in housing (14) is

connecting linkage will cause sleeve control shafts

controlled by bypass valve (12). Pressure of the

(19) to turn.' With this movement of the sleeve

fuel at FULL LOAD is 30 5 psi (2.1 0.4

control shafts, levers (31) will lift sleeves (32) to

kg/cm2). If the pressure of fuel in housing (14)

make an increase in the amount of fuel sent to the

gets too high, bypass valve (12) will move (open)

engine cylinders.

to let some of the fuel return to the inlet of fuel

transfer pump (11).

When starting the engine, the force of over fuel-

ing spring (27) is enough to push thrust collar (28)

Lever (15) for the governor is connected by

to the full fuel position. This lets the engine have

linkage and governor springs (25) to the sleeve

the maximum amount of fuel for injection when

control shafts (19). Any movement of lever (22)

starting. At approximately 400 rpm, governor

will cause a change in the position of sleeve control

weights (30) make enough force to push spring

shafts (19).

(27) together. Thrust collar (28) and spring seat

(26) come into contact. From this time on, the

When lever (15) is moved to give more fuel to

governor works to control the speed of the engine.

the engine, lever (22) will put governor springs (25)

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |