|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-3835-222-BD

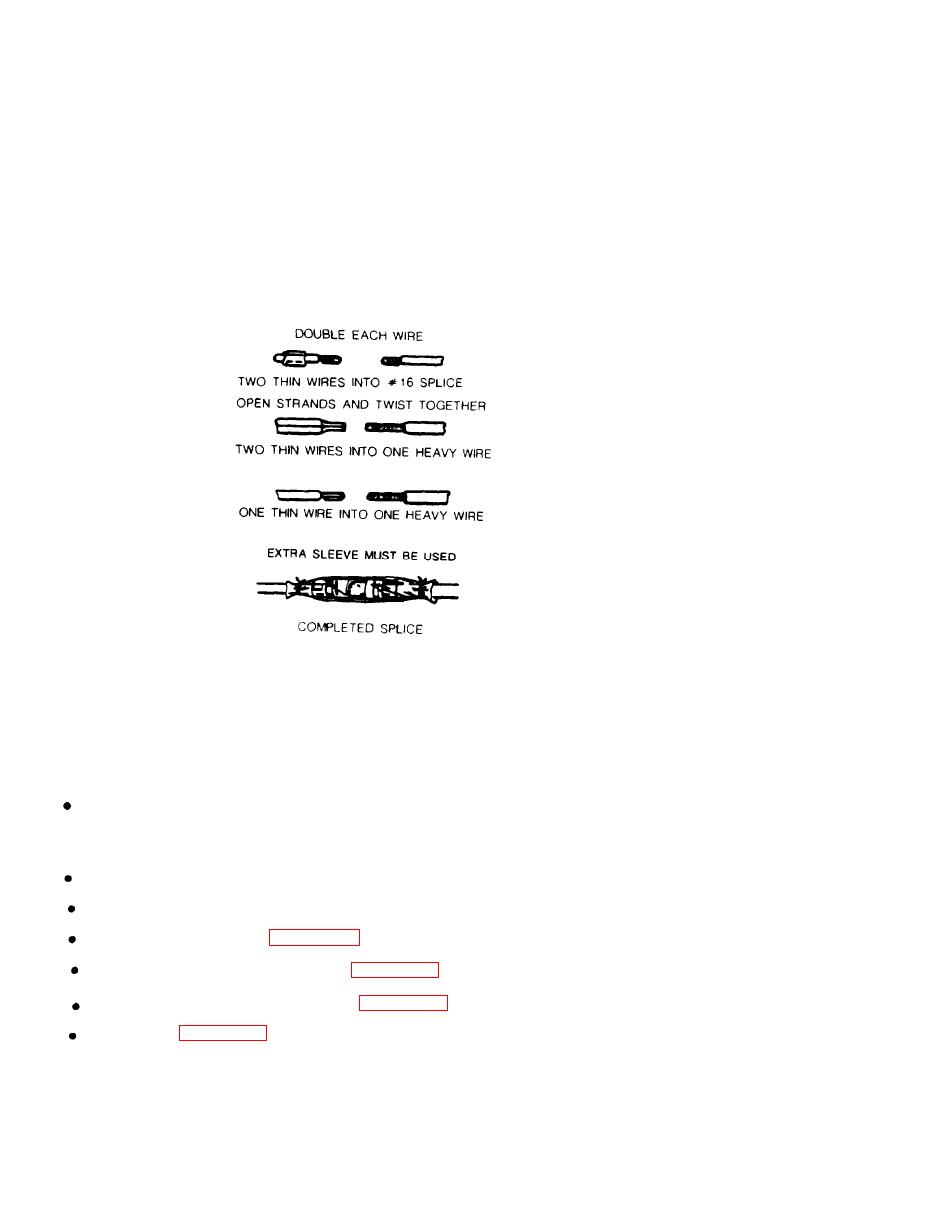

Option 3: Splicing Different Size Wires:

a. Strip broken wire ends, strip enough insulation to allow the smaller wire to be doubled as shown.

b. Install plastic sleeve or shrink tubing, if available, over one end of broken wire.

c. Connect wires by using a splice or terminal lug prepared as in Option 2.

d. Crimp splice or lug to secure the wires.

e. Slide the sleeve or tubing over the splice or tape to insulate the conductor.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the

equipment using standard maintenance procedures.

7-12. Cable, Heavy Duty, Damaged. Heavy electrical cables are more difficult to repair than small

wires and they Can be repaired using several different methods. Splicing procedures can be used

to repair a break

Personnel/Time Required:

1 soldier - 15 - 60 minutes

Materials/Tools:

Bolt, Short With Matching Nut

Lugs, Terminal, Screw Clamp, or Clamp, small hole

Cable Clamp and Solder (appendix C, section Ii, item 33)

Soldering Iron Or Torch and Soder (appendix C, section II, item 33)

Insulting Sleeve, Or Tape, Electrical (appendix C, section II, item 41)

Wire, Safety (appendix C, section II, item 51)

Procedural Steps:

Option 1: Splicing cable with terminal lugs:

7-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |