|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-3835-222-BD

Procedural Steps:

a. Gain access to radiator.

b. Inspect the radiator and pinpoint the leak location.

c. Drain the coolant.

d. Using side cutters, cut or break away the cooling fins from the coolant tubes, 1 to 2 inches each

side of the leak

e. Cut the coolant tube at the leak location, taking care not to tear or puncture the other tubes.

f. Squeeze the tube ends together and fold over on itself approximately inch.

h. If no epoxy or solder is available, fold the tube once more H-inch to restrict the coolant leaks.

i. Reinstall the coolant. Inspect radiator for leaks.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the

equipment using standard maintenance procedures.

6-10. Hose Clamp Broken. A broken hose clamp will allow the hose to leakcoolant and cause engine

overheating. The clamp must be replaced or a substitute improvised to regain a sealed cooling

system. If a replacement clamp is not available wire can be used as a substitute. Care must be

taken that the wire does not loosen.

Personnel/Time Required:

1 soldier - 5 - 10 minutes

Materials/TooIs:

Deleted.

Procedural Steps:

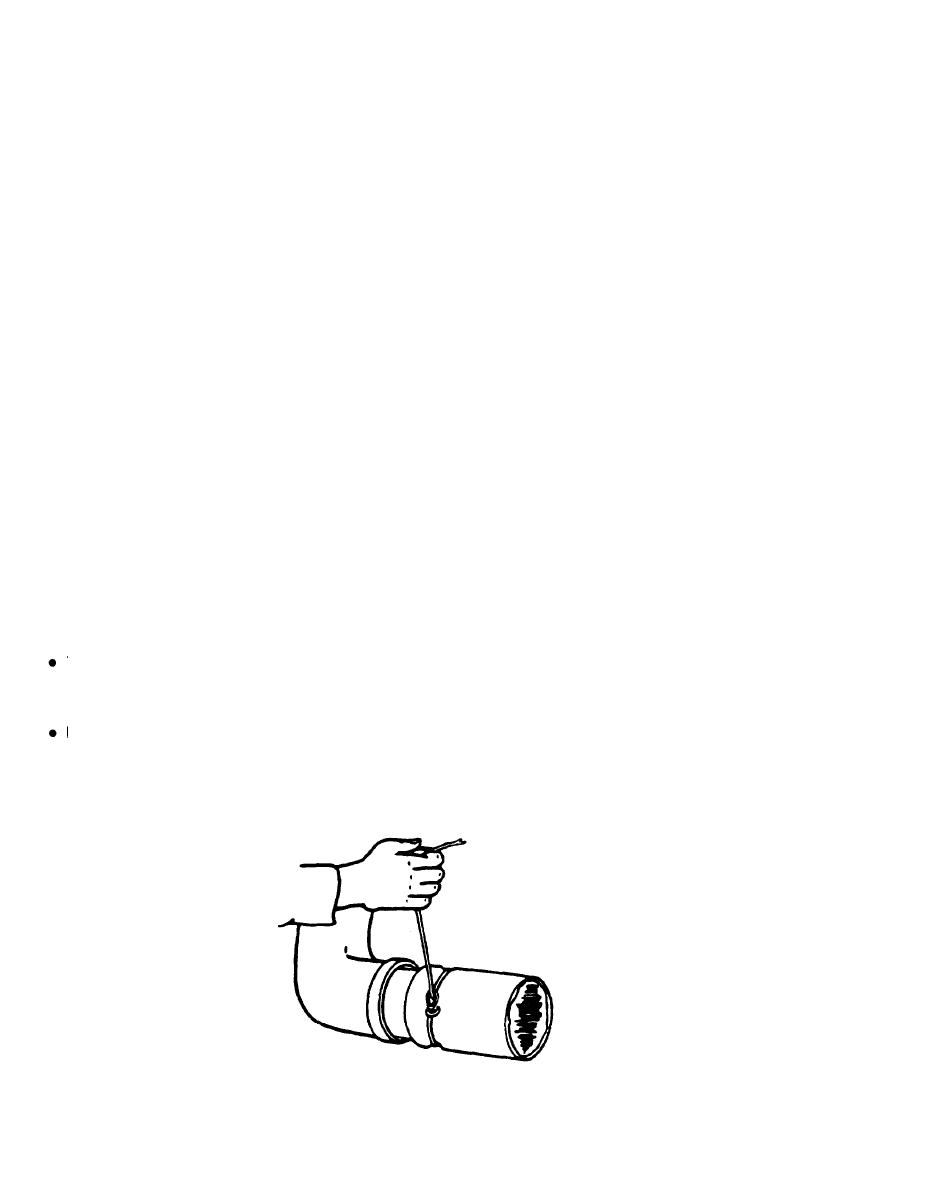

a. Make a loop in one end of a wire. Twist the wire so that a permanent loop is formed.

6-6

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |