|

|||

|

|

|||

|

Page Title:

Pressure Regulator |

|

||

| ||||||||||

|

|

TM 3-1040-220-34&P

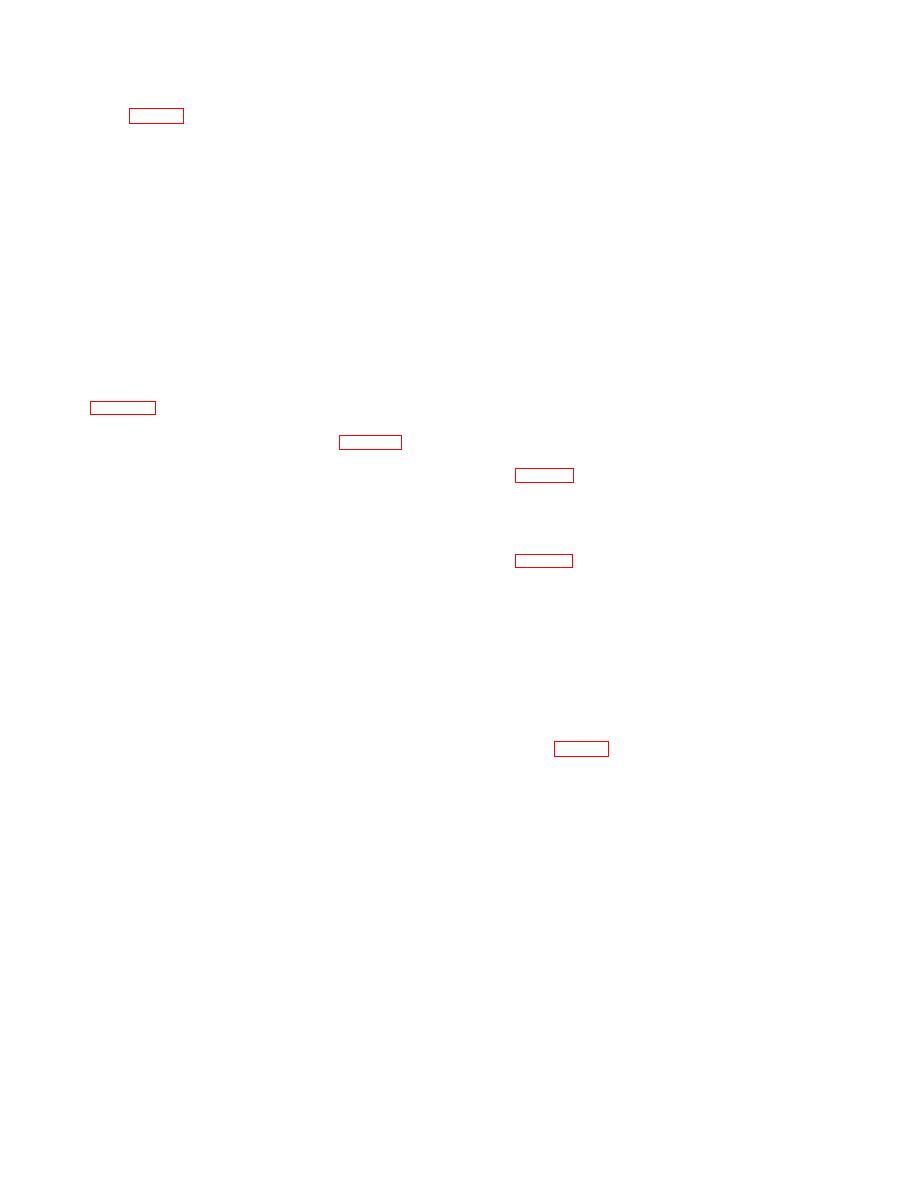

Legend for fig 2-2:

12 Washer

1 Adjustment nut

13 Poppet valve

2 Lock nut

14 Retainer seat preformed packing

3 Spring guide

15 Poppet preformed packing

4 Spring cartridge

16 Seat retainer

5 Spring guide

17 Retainer screen

6 Coated piston

18 Poppet seat

7 Piston preformed packing

19 Seat preformed packing

8 End nut

20 Retainer preformed packing

9 Lock wire

21 Lock wire screw

10 Washer

22 Regulator body

11 Spring

until the port from the inlet to the outlet is closed and

2-3. Pressure Regulator

further passage of air is blocked off.

b. Maintenance. Direct support maintenance

a. Description and Function. The pressure regulator

personnel are authorized to replace the pressure

(23, fig.

2-1) is a spring-controlled,

piston-type

regulator.

regulating device. The main operating components of

(1) Removal.

the regulator are a spring cartridge (4. fig. 2-2), an

(a) Open the globe valve (high pressure control)

adjustment nut (1), a coated piston (6), a poppet valve

(18, Fig. 2-1).

(13), and a poppet return spring (11). High-pressure air

(b) Slowly open the angle valve (charging valve)

is connected to the inlet of the regulator and the outlet is

(36) and allow pressure in the compressed gas cylinders

connected to the low-pressure system in which the air

(8 and 9) to bleed off.

pressure is to be regulated. Low-pressure air in the

(c) Operate manual lever on safety relief valve

outlet passes through an internal port to the piston

(40, fig. 2-3) to relieve low-pressure system pressure.

chamber. This pressurized air pushes against the

(d) Open lever plug valve (25) to allow the low

coated piston (6), which in turn presses against the

pressure plumbing components to bleed back through to

spring cartridge (4). Depending upon the tension placed

the safety relief valve (40).

on the spring cartridge (4) by the adjustment nut (1), the

(e) Disconnect the nonmetallic hose assembly

piston will move either against or away from the spring.

(17) and quick-disconnect coupling half (16) from the

If the pressure in the outlet is insufficient to overcome the

quick-disconnect coupling half (15).

spring tension, the spring cartridge (4) forces the coated

(f) Release luggage catches from catch strikes

piston (6) against the poppet valve (13). The poppet

that secure pressure group to base group.

valve (13) then slides along its guide channel and

Remove pressure group as a unit.

opens a port which connects the inlet to the outlet. High-

(g) Disconnect flare nuts of two tube assemblies

pressure air then passes through to the low-pressure

(1 and 31, fig. 2-1) from pipe tee (33) using a wrench.

system and when this pressure builds up to the proper

(h) Using a wrench, disconnect the dial indicating

value, the piston (6) is pushed against the spring

pressure gage (29) and the nonmetallic hose assembly

cartridge (4). As the piston (6) moves, the poppet return

(27 at the swivel connector end of the hose or at elbow

spring (11) forces the poppet valve (13) to follow the

(25).

piston (6)

2-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |