|

|||

|

|

|||

|

Page Title:

Organizational Monthly Preventive Maintenance Checks and Services Chart |

|

||

| ||||||||||

|

|

TM 11-6140-224-13&P

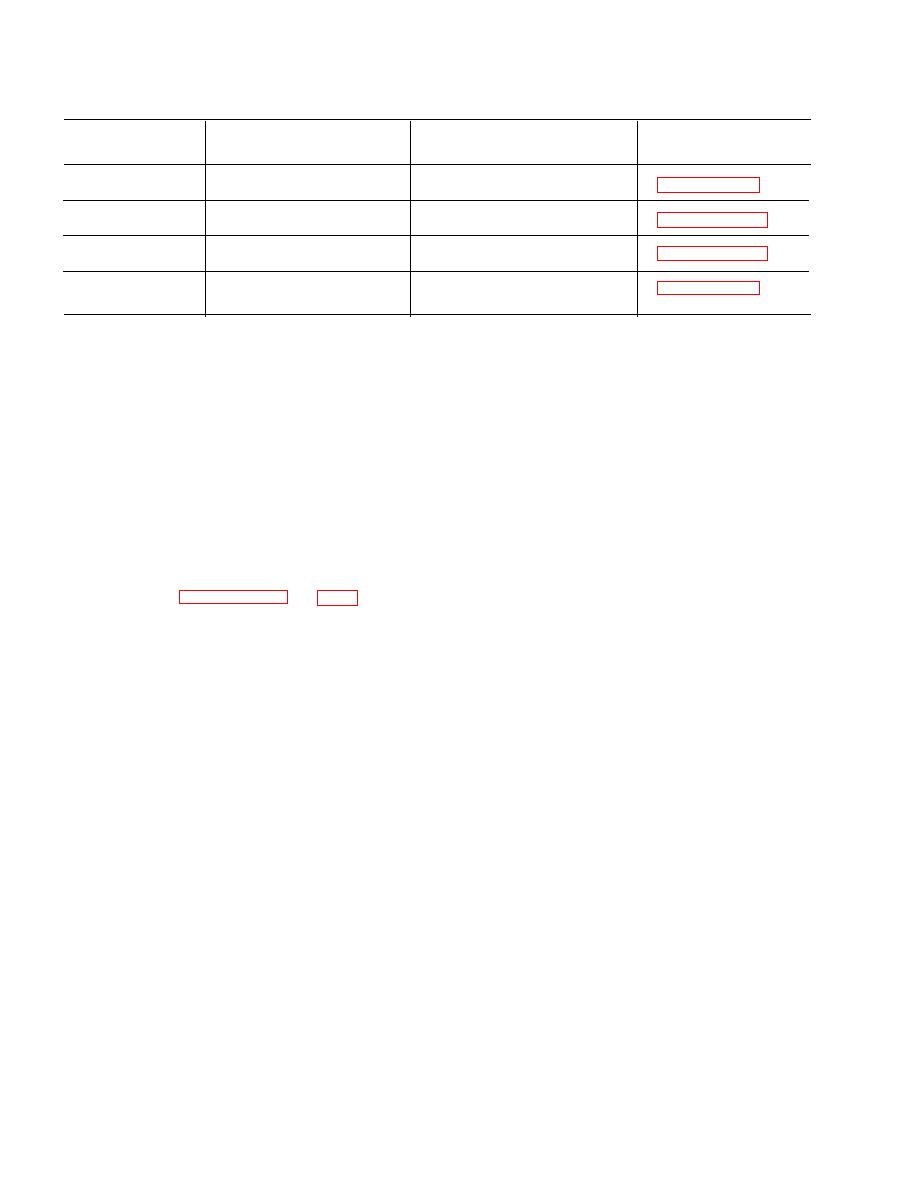

4-6. Organizational Monthly Preventive Maintenance Checks and Services Chart

Sequence

Item to be

No.

Inspected

Procedure

Reference

1

Overall Battery

Inspect battery.

2

Overall Battery

Clean battery.

3

Overall Battery

Charge battery.

4

Overall Battery

Check leakage current

of each battery.

4-7. Visual Inspection

Many causes of battery failure may be detected by visual inspection. Because the battery cannot be disassembled by an

organizational repair technician, visual inspection is limited to observing the assembled battery. Only the fuse and dust cap

can be replaced, obvious corrosion or contamination cleaned and loose nuts tightened at organization maintenance; for all

other damages refer to higher category of maintenance. Release the snap fasteners and remove the battery cover. Check

the storage battery for damage as indicated in (a) through (e) below:

a. Battery box or cover scratched or dented.

b. Connectors bent or broken.

c. Connector cover missing or bent.

d. Loose or missing control module holddown nuts.

e. Blown or missing fuse.

4-8. Organizational Testing

Testing will supplement the visual inspection in determining the cause of troubles which may occur in the storage battery.

The tests given in paragraphs 4-9 and 4-10 may indicate an inoperative control module, defective cells, open wiring, or

electrical leakage between the cells and the battery box.

4-9. Electrical Leakage Test

Prior to performing this check of the battery, all electrical cables should be disconnected from the unit under test. The

electrical leakage test will indicate conditions that may cause the storage battery to discharge faster than normal or to

discharge when not in use.

a. Use Multimeter, or equivalent, set to indicate on the 50 volt scale at 1,000 ohms per volt.

b. Connect positive lead of multimeter to positive (+) terminal of battery connector.

c. Connect negative lead to bare metal or unpainted area of case or connector shells.

d. If the TS-352B/U indicates less than 1 volt, set it to indicate on the 10 volt scale at 1,000 ohms per volt. The

voltage indicated must be less than 1 volt.

NOTE

If the voltage is greater than 1 volt, leakage is present. The battery should be

turned over to support

maintenance.

e. Connect negative lead of multimeter to negative (-) terminal of battery.

f. Connect positive lead of multimeter to unpainted area of battery case such as the latches or screws on the

connector.

g. Indications should be the same as those obtained in d above. If both indications are below 1 volt return battery to

normal service.

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |