|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

T.O. 3lW2-2GSC24-2

TM 11-5805-688-14-1

NAVELEX 0967-LP-545-3010

15. Carefully inspect entire wiring plane surface

6-30.

PREVENTIVE MAINTENANCE.

for evidence of loose foreign materials such as broken

wire ends. Remove such items before proceeding

6-31. GENERAL. Preventive maintenance of the

multiplexer set consists of periodic self-testing and lamp

16. Tilt connector panel partially into place and

testing, calibration of reference timing sources, and

mate connectors P1 and P2 disconnected in step 7

routine inspection and cleaning. Table 6-5 lists required

preventive maintenance tasks, together with their

17 .Place connector panel against multiplexer

performance frequency.

Preventive maintenance

set chassis and install 22 screws and washers removed

procedures are presented in the following paragraphs.

in step 5.

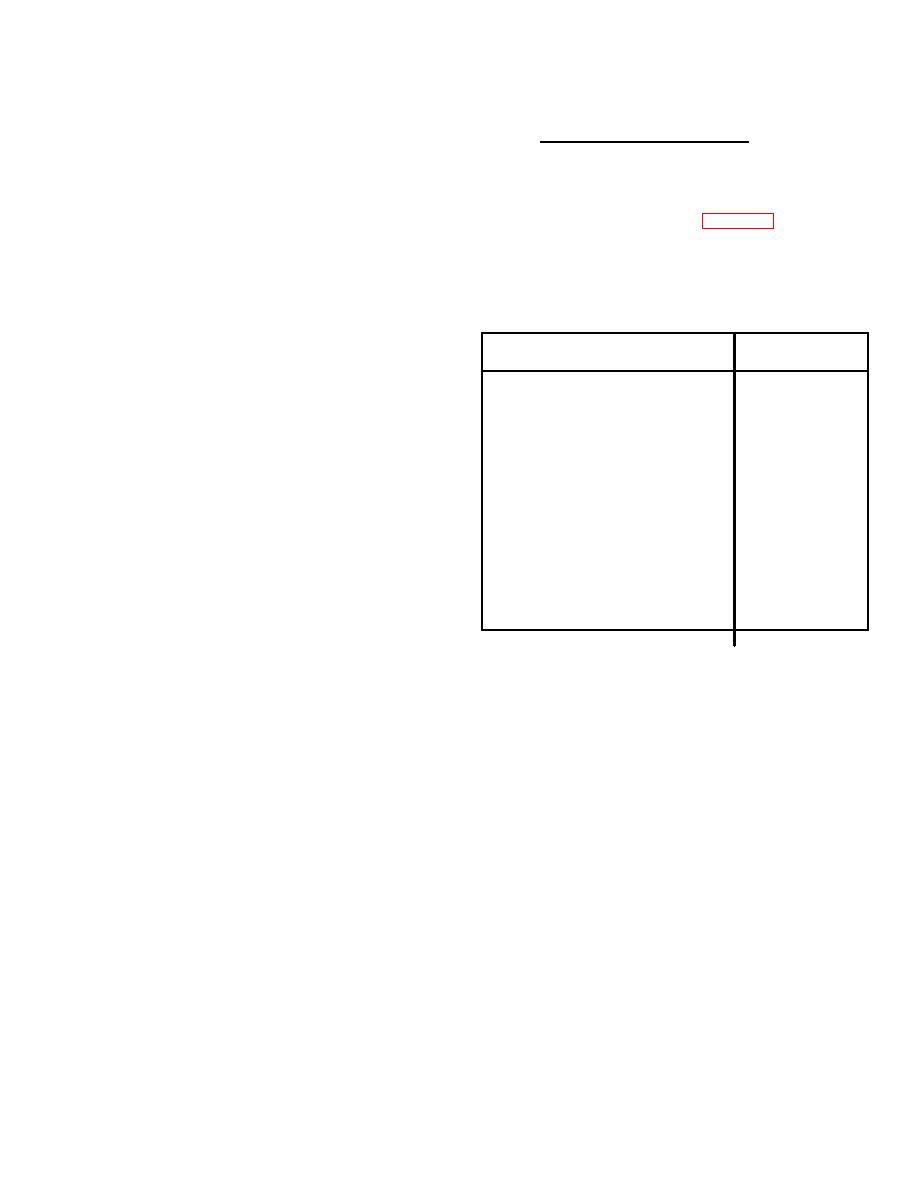

Table 6-5.

Preventive Maintenance Summary

18. Connect cables removed in step 4 to

POWER INPUT and REMOTE ALARMS receptacles.

Preventive Maintenance

Task

Task

19. Mate all signal cables disconnected in step

3 to connector panel.

Perform diagnostic self-test.

Daily

20. If multiplexer set chassis was extended

Perform lamp test

Daily

and/or tilted prior to start of backplane repair, return

chassis to its normally installed position and secure it to

Calibrate reference

28 days

mounting rack.

timer assembly.

6-29. PAINT TOUCHUP. Touch up chips, scratches,

Calibrate transition

28 days

or other minor damage on exterior painted surfaces of

encoder/timing recover assembly.

the multiplexer set chassis as follows:

Clean cooling air filters

28 days

1.

Lightly sand the affected surface area,

using a medium grade of sandpaper. Ensure that any

Perform visual inspection.

28 days

visible signs of corrosion are removed.

2.

Using a small clean brush, apply one coat

6-32. DIAGNOSTIC CIRCUIT SELF-TESTING. Self-

of zinc chromate primer per MIL-P-8585 to any exposed

testing of the multiplexer set diagnostic circuits is

metal surface area. Let surface dry.

performed to determine that the circuits are capable of

detecting and displaying faults occurring in the operating

3. Using a small clean brush, apply one coat of

circuits. Perform a diagnostic self-test as follows:

semigloss enamel per TT-E-529 (color No. 26440 per

FED-STD595) to entire sanded area. Let surface dry

6-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |