|

|||

|

|

|||

|

Page Title:

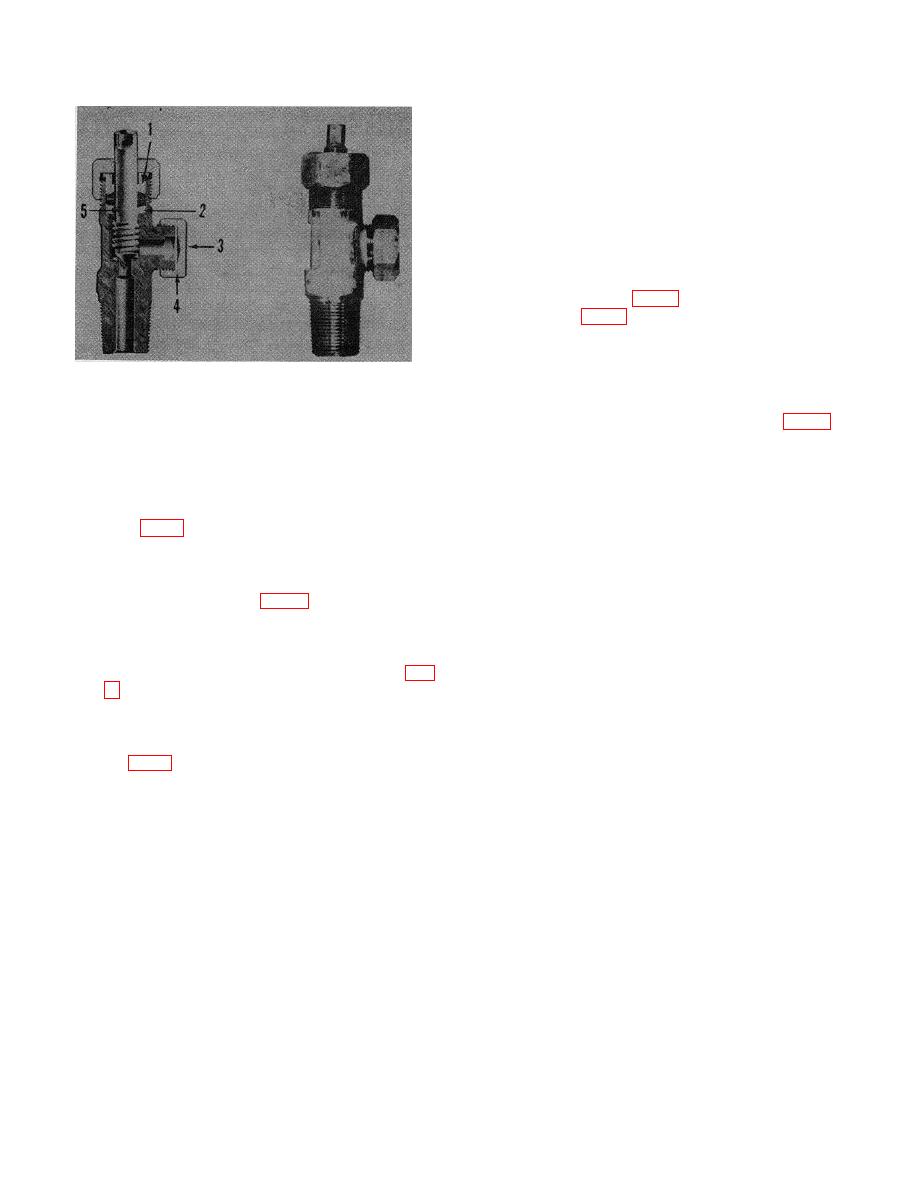

Figure 5. Chlorine lnstitute valve for 1-ton |

|

||

| ||||||||||

|

|

b. Type D. The type D 1-ton container is used to

ship and store chemical agents that are either liquid or

gaseous at atmospheric pressure. It is identical with the

type A container except for the inside diameter of the

eduction tubes and eduction tube outlets as described

below.

(1) Eduction tubes. The inside diameter of

the eduction tubes in the type D container

is 1 inch.

(2) Valves.

One-inch Chlorine Institute

valves (fig. 5) or one-inch angle valves

outlets. Angle valves are used only in

containers under low internal pressure.

Chlorine Institute valves are used in

containers under high pressure.

1 Packing gland

2 Packing ring

3 Cap

substitute for types A and D and can be filled with any

4 Gasket

type of liquid or gaseous chemical agent.

It is

5 Stem

approximately the same size as the types A and D and

Figure 5. Chlorine lnstitute valve for 1-ton

has the same capacity. It weighs 900 pounds empty

container.

compared with the 1,600-pound empty weight of types A

and D. The type E container is a closed cylinder, 30

bonnet fig. 3) is fastened over the valves by three

inches in diameter, made of 9/32-inch steel. Protective

bonnet clips and a bonnet-locking clip.

housings (11 and 5) welded to the front and rear ends of

the container project beyond the front and rear heads.

(2) Eduction tubes. Two 1/2-inch inside diameter

The overall length of the type E container is 82 1/2

steel eduction tubes (fig. 4) extend into the

inches.

container from the front head. Either eduction

tube can be used for emptying or venting the

(1) Front head. The front head is a convex dome

container.

welded to the front end of the container. Two

eduction tube outlets (6), 14 inches apart, are

located in the front head.

Each outlet is

cap (3) fitted with a gasket (4) covers the valve

threaded to receive a 1-inch valve (1). Three

outlet when the valve is not in use.

tapered plugs (10) are screwed into 3/4-inch

(4) Valve-opening wrench. A valve-opening wrench

holes spaced equally around the outer edge of

(1, fig. 2) is used to open and close the valves.

the front head. The plugs will blow out when the

It is attached to one of the valves when the

internal pressure becomes too high. Fusible

container is being transported or stored.

plugs are installed when the container is filled

(5) Rear head. The rear head of the type A 1-ton

with chlorine; nonfusible plugs are installed

container is of the same construction as the

when it is filled with other chemical agents. A

front head, but the rear head has no eduction

circular protective cover (9), bolted to the front

tube outlets and no shipping bonnet or bonnet

protective housing by

clips.

(6) Identification. The front rim of the container is

marked with the nomenclature of the container,

the water capacity in pounds, the drawing

number, serial number, lot number, the symbol

of the agent in the container, and the date the

container was tested.

AGO 9020A

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |