|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TB9-2510-242-40

Also, smaller weld beads require less heat input than larger ones. Use a minimum of three weld passes per

crack when welding T- Steels. All flux, scale, and oxide must be removed from each weld bead prior to

depositing an overlapping bead. Mechanical means such as a hammer or wire brush are recommended. All weld

passes, except for the first and final, must be peened to reduce undesirable stresses caused during shrinkage of

the weld material. The peening process is most effective while the weld and base metal are still hot.

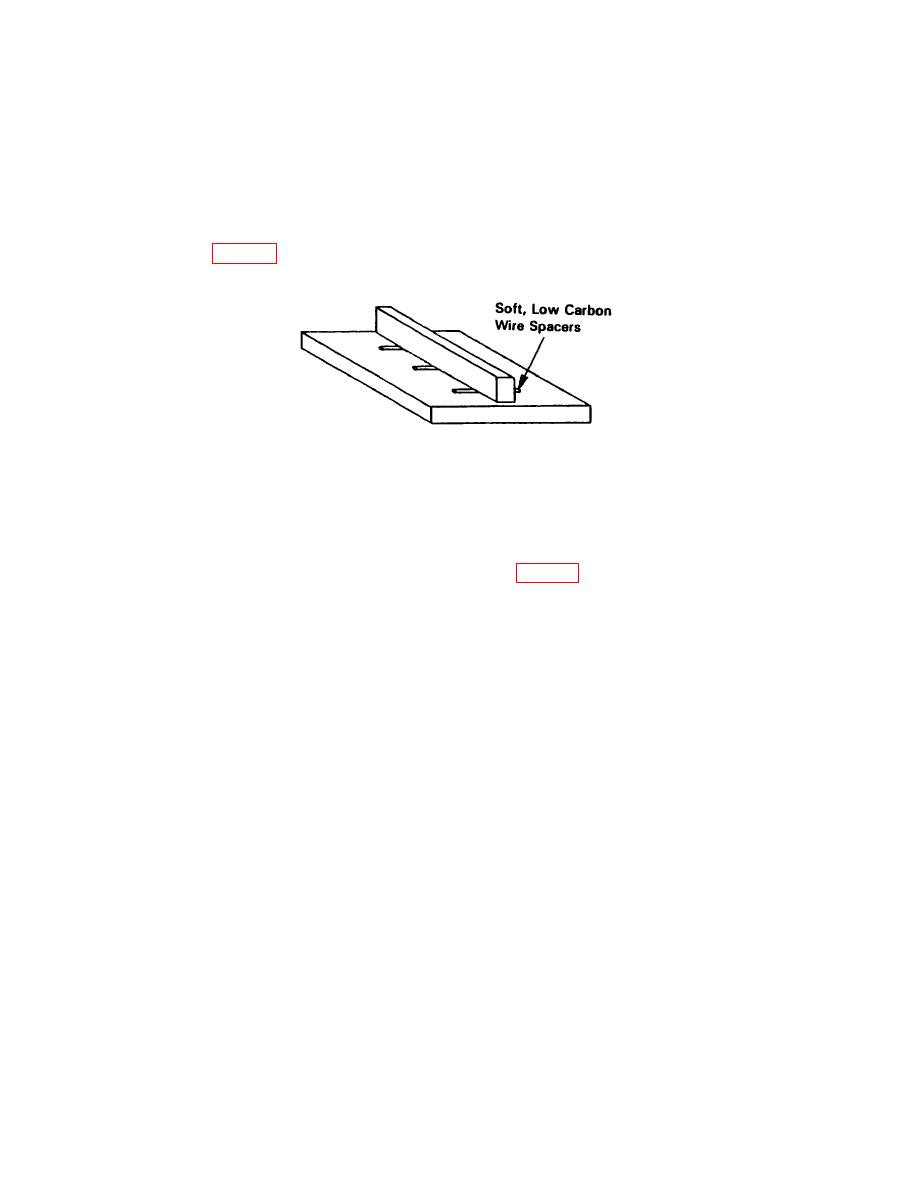

d. Soft Wire Spacers. To reduce the high stresses caused by weld shrinkage, soft wire spacers can be used for

fillet welds. The spacers can be any low carbon steel wire. Because the wire material is more ductile than the

high strength weld bead, wire acts like a cushion or buffer between the welded members, thus reducing weld

stresses. (See Figure 2.) Soft wire spacers are normally used for joint thickness of 2 inches or greater.

Figure 2. Wire Spacers

e. Surface Weld Fillet Welds. The incorporation of surface or butter welds at the toe section of fillet welds will

provide additional relief from stresses due to weld shrinkage. Prior to depositing a fillet weld, determine the

approximate location of the weld toe. Deposit a minimum of 2 to 3 surface weld beads with a low-strength weld

metal. Complete the mufti-pass fillet weld using the roper, full strength welding electrode. Cover only half of the

surface weld beads with full strength material as shown in Figure 3. The surface weld will provide additional

ductility at the highly stressed toe section of the fillet weld and will reduce the risk if cracking due to shrinkage.

Surface bead fillet welds are normally used for joint thickness of 2 inches or greater.

E-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |