|

|||

|

|

|||

|

Page Title:

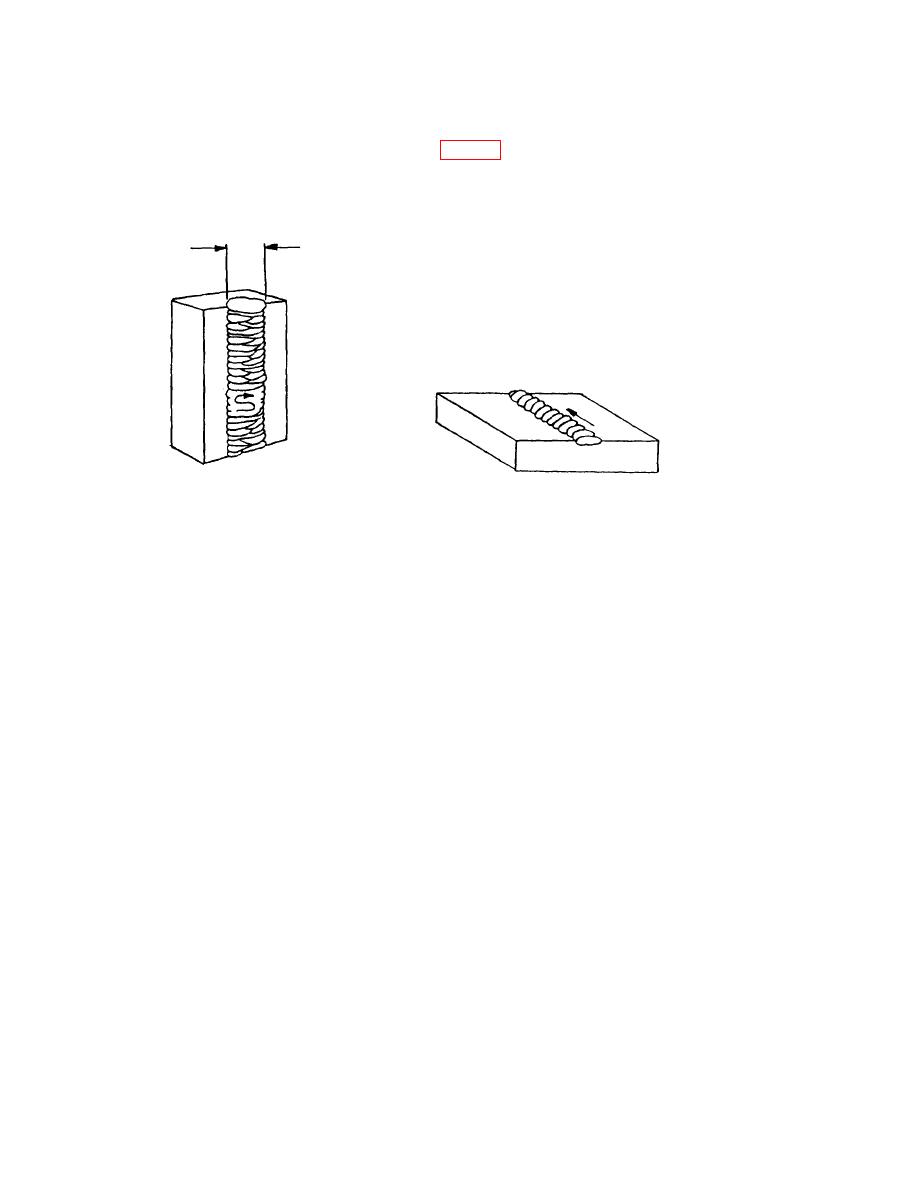

Figure 1. Straight and Partial Weave Welding Methods. |

|

||

| ||||||||||

|

|

TB9-2510-242-40

a. Stringer Bead vs. Weave Bead Technique. It is desirable to minimize the heat input while welding T-1 steels.

With the stringer bead method, weld beads are deposited in a straight line; with the weave bead method,

weld

beads are deposited in a zigzag formation. (See Figure 1) The use of stringer beads reduces the amount of heat

input, because the forward weld travel speed is faster. Therefore, the stringer bead technique should be used

instead of the weave bead technique. The exception to the stringer bead requirement occurs when welding in the

vertical position. In this case, a partial-weave technique may be used to facilitate welding. However, the total

weave shall not be greater than twice the electrode diameter.

Maximum width =

2 X Electrode Die

Partial-Weave Technique

Straight Bead Technique

Vertical Position Only

All Positions

Figure 1. Straight and Partial Weave Welding Methods.

b. Back Step Technique. When using low-hydrogen electrodes, the back-step method must be used for each

string of weld bead. The purpose of the back-step method is to reduce weld porosity at the arc initiation point,

thus resulting in a stronger weld. The following is the back-step method.

(1)

Strike the arc one in inward from the intended starting point of the weld string.

(2)

Weld outward to the intended starting point.

(3)

Reverse direction and weld back over the one in of newly deposited weld.

(4)

Continue welding along the crack.

c. Multiple Pass Welding . Use small, multiple weld beads, as opposed to large, single or double weld beads. The

small, multiple weld beads will exhibit better notch toughness due to the tempering effect of additional weld

passes.

E-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |