|

|||

|

|

|||

|

Page Title:

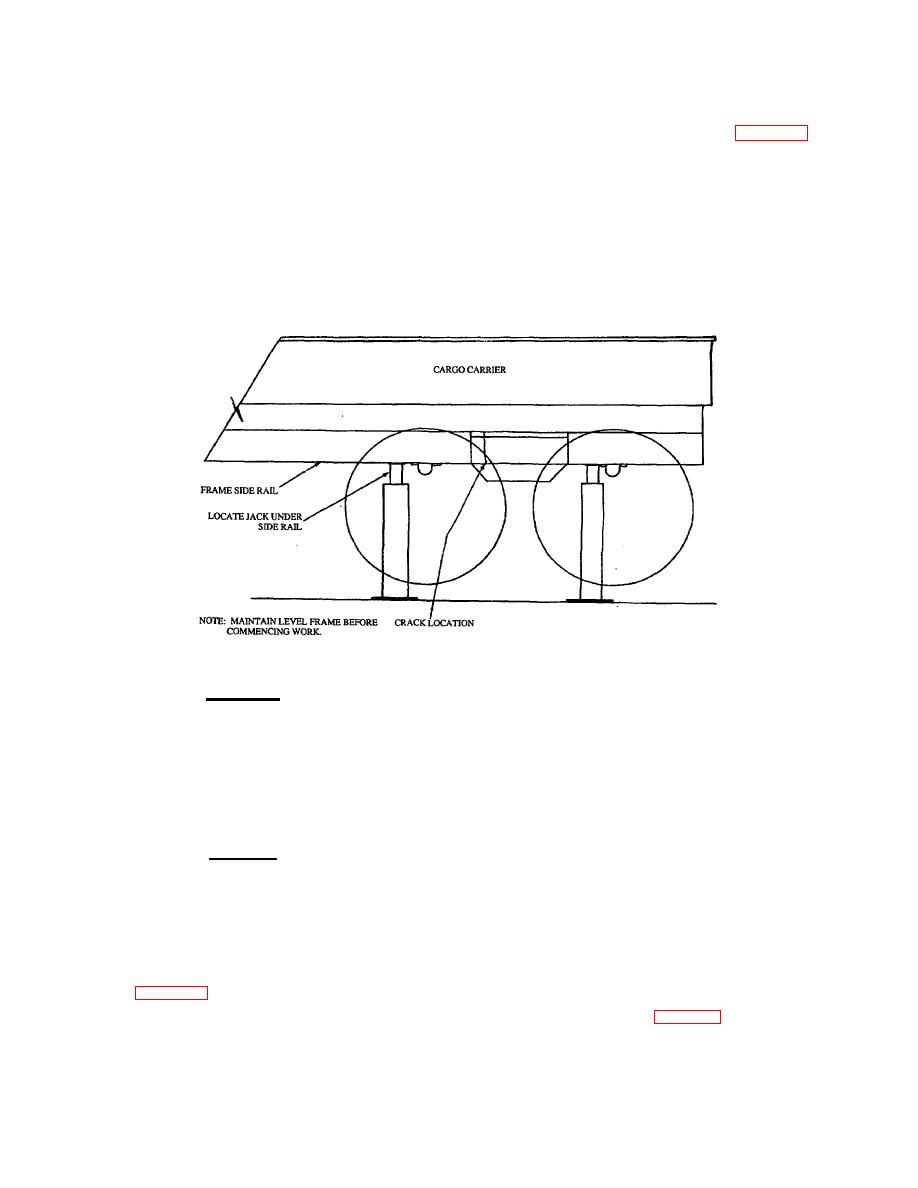

Figure 24. Location of Jacks or Supports |

|

||

| ||||||||||

|

|

TB 9-2300-247-40

Floor surface must be flat within 1-inch in 24 feet. Floor

e.

Carefully jack up and evenly support the

clean of dirt, grease, oil, or debris.

vehicle frame to gain access to the area to

be repaired as shown in Figure 25. Provide

Equipment Condition: Vehicle empty and vehicle

firm support directly under the area to be

undercarriage clean and completely free of mud,

repaired and as shown.

dirt, and debris.

f.

Remove hold down bolts securing cargo

d.

Perform the necessary removal of

area and raise cargo area approximately 4

components, service lines, electrical wiring,

to 6 inches of clearance above side rails to

etc., as required to gain access to the

gain access to for working space.

proposed repair.

g.

Lower or remove rear axle assembly, side

plate, and frame bracket.

Figure 24. Location of Jacks or Supports

i.

If the break (crack) does not extend through

WARNING

the entire cross section of the rail, a 3/16-

Use Only effective chip guarding

inch diameter hole may be drilled at the

equipment, protective equipment and

extreme edges of the crack. This will

protective clothing (goggles, shields,

reduce the concentration of the defect at

gloves aprons, etc.) when doing any

the tip of the break.

drilling, grinding, or welding. Failure

to follow this warning could result in

j.

Using a suitable grinder, bevel the edges of

injury to personnel.

the break and follow the repair procedures

indicated in paragraphs m thru y.

CAUTION

When cutting at the edges of frame

k.

Separate the vehicle frame at the break to

rail break, care should be taken not to

be repaired and scarf or bevel the edges of

remove excessive metal and create

the broken sections and cut a V-shaped

the need for an unnecessarily large

groove at both sides of the break.

welded area.

l.

To assure accuracy of alinement, butt the

h. Remove rivets and bolts as required and as

two broken sections together and clamp

described in Chapter 1.

with C-clamps, a straight edge or angle iron

as shown in figure 28.

23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |